Challenge in reagent dosing.

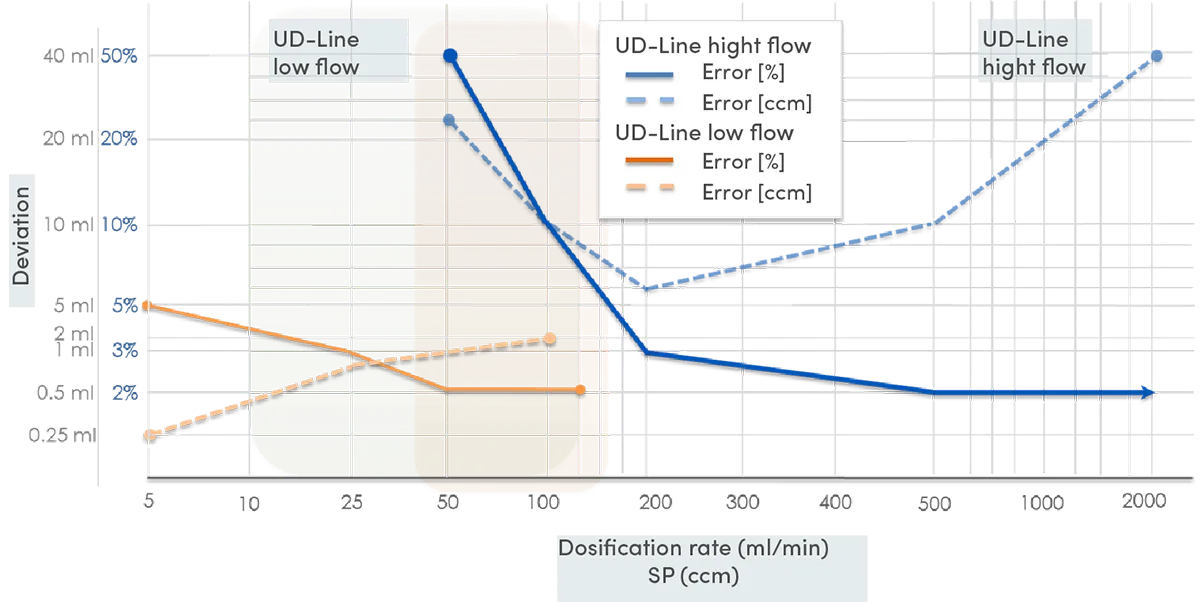

In the dosage of reagents for mining there is the main challenge of the unknown chemical formulation of reagents, coupled with an evolution to stronger collectors which require a smaller amount of flow to dose. The UD-Line® Reagent Dosing System integrates the measurement of the dosed flow and its design is based on the correct selection of materials according to the chemical compatibility of the reagent used, resulting in a high precision and low maintenance system.

Unknown chemical formulation, important characteristics:

a) Corrosives (Collectors that attack SS316)

b) Solvents (Collectors that attack plastics)

c) Flammable (Diesel and collectors)

d) High risk to health (NaSH, CuSO4, etc.)

The dosing system design follows this classification of the reagents. This makes it difficult to define the materials of the dosing system components in contact with the reagent, especially seals and gaskets.

The evolution to stronger collectors, which imply doses lower than 20 ml / min even in large mining. Micro flow dosing system design (<100 ml / min).

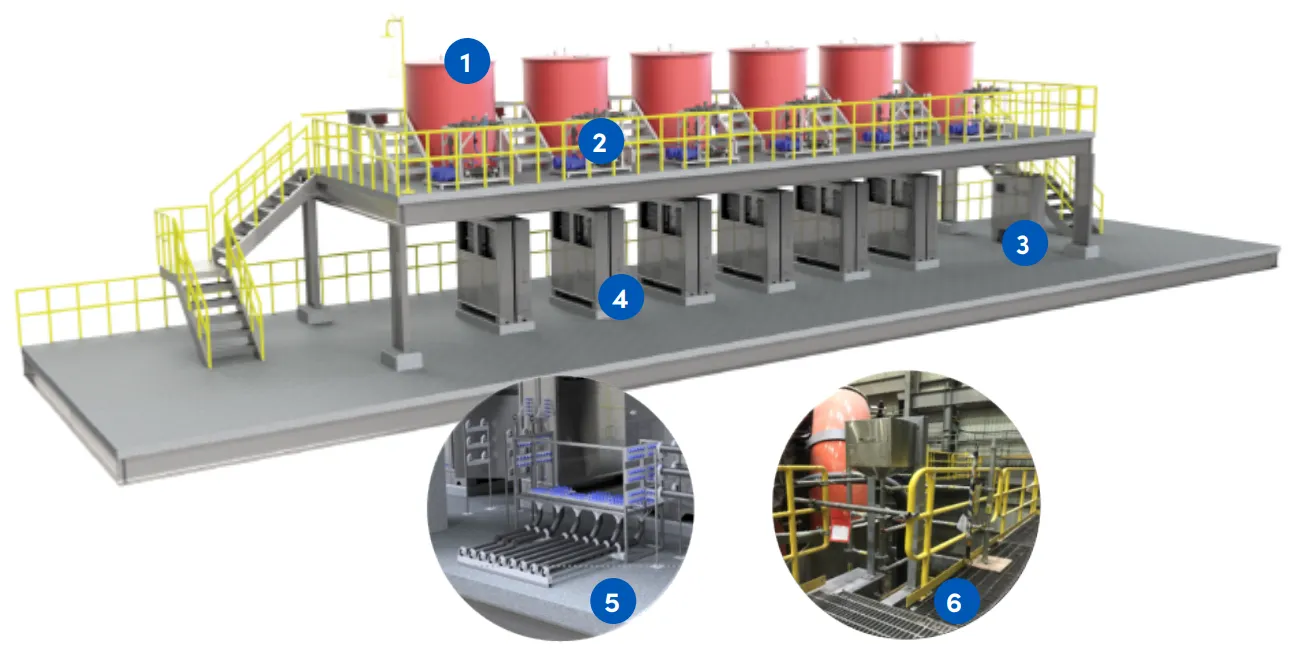

System characteristics

System Components

Models

Multiplex system for micro doses lower than 500 ml/min. Typical installation: Collectors and frothers.

DETAILS

2 multiplexer units

Up to 12 channels

Up to 2 reagents

Process material: PTFE/CPVC/SS

Flow range: 5 - 300 ml/min

Multiplexed dosing

Multiplex system for doses between than 0.5 - 4 l/min. Typical installation: Collectors, xanthates and frothers.

DETAILS

2 multiplexor units

Up to 12 channels

Up to 2 reagents

Process material: PTFE/CPVC/SS

Flow range: 500 - 4,000 ml/min

Multiplexed dosing

Continuous flow system for doses between than 0 - 10 l/min. Typical installation: NaSH, defoamers, xanthates.

DETAILS

Continuos flow dosing

Up to 12 channels

Up to 2 reagents

Process material: PTFE/CPVC/SS

Flow range: 0 - 10,000 ml/min

Continuous flow system for doses higher than 10 l/min. Typical installation: NaSH, flocculants, dispersants.

DETAILS

Continuos flow dosing

Up to 8 channels

Up to 2 reagents

Process material: PTFE/CPVC/SS

Flow range: 0 - 10,000 ml/min

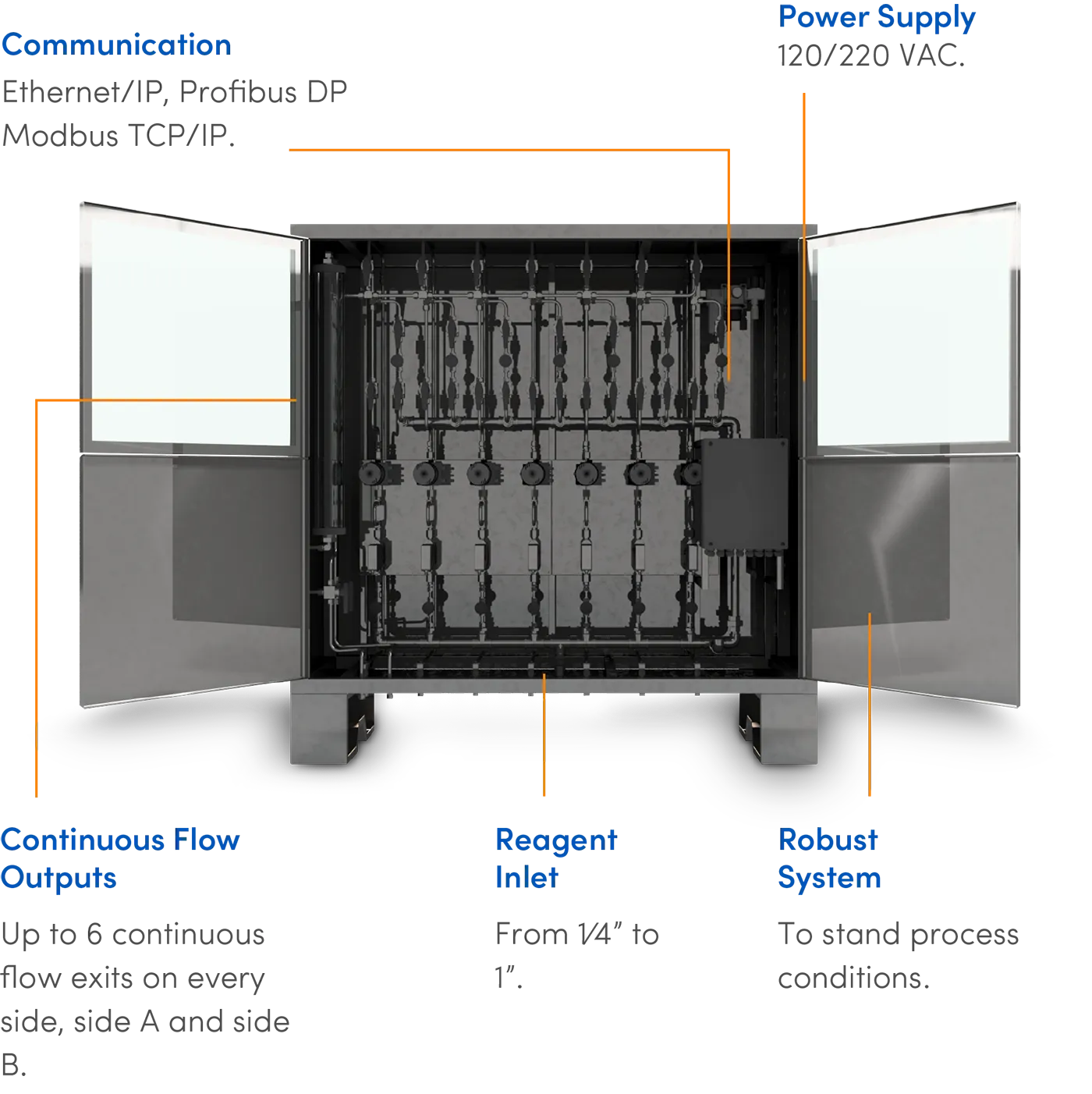

Plug & Play container where the UD Line and Master controller are located, the system is pre-commissioned and ready to connect electrical power, industrial communication and reagents inlets & outlets, making it easy and faster to get it up and running.

DETAILS

Custom & sturdy design

Plug & play

Ready for installation

Pumping station system for main reagent line from the storage tanks to the UD Line.

DETAILS

Operation pump & bypass pump

Filtration system

Integrates to UD Line control

VFD regulated depending on the desired flow

Plant: Concentradora “La Caridad”

Location: Nacozari, Sonora, Mexico.

Reagents: 4

Teuton1018

Frother

C-8944

T-609

Flex 31

Dosage Points: 70

24 UD-Line

Plant: Concentradora II y Planta de Molibdeno II “Buenavista del Cobre”

Location: Cananea, Sonora, Mexico.

Reagents: 8

T-1018

T 100-50

SPRI 156

Flex 31

NaSH

NaCN

MIBC

Antifouling

Dosage Points: 120

46 UD-Line

Plant: ASARCO South Mission, Grupo Mexico.

Location: Arizona, USA.

Reagents: 2

A238

PINEOIL

Dosage Points: 4

1 UD-Line

Plant: Toquepala Expantion Project, SPCC.

Description

Reagents: 10

MCC-C3320(C1)

AR-G431 (C2)

AR-3322 (C3)

CC-1225 (Esp)

Diesel2

NaSH

Antiscalant

Sulfuric Acid

Antifrother

Dosage Points: 142

18 UD-Line

Plant: Concentradora I “Buenavista del Cobre”

Location: Cananea, Sonora, Mexico.

Reagents: 4

T-1018

Frother

C-8944

T-609

Dosage Points: 26

10 UD-Line

Plant: Minera Chinalco Peru S.A.

Location: Toromocho, Peru.

Reagents: 1

PAX

Dosage Points: 3

1 UD-Line

Plant: Madero Mine, Grupo Peñoles.

Location: Zacatecas, Mexico.

Reagents: 3

FrotherTeuton100

Collector Flotec1234

Aerophine

Dosage Points: 12

4 UD-Line

Plant: Unidad Madero, Grupo Peñoles.

Location: Zacatecas, Mexico.

Reagents: 2

Xantathe

Sodium Cyanide

Dosage Points: 8

2 UD-Line

Plant: Palmarejo, Grupo Coeur.

Location: Palmarejo,Chihuahua.

Reagents: 3

Xanthate

Frother

Promoter

Dosage Points: 8

1 UD-Line

Plant: ASARCO North Mission, Grupo Mexico.

Location: Arizona, USA.

Reagents: 2

Collector

Frother

Dosage Points: 12

2 UD-Line