Early short circuit detection system in electrolysis cells.

The electrolysis process demands a large amount of energy due to the high currents used. The efficiency of the process corresponds to the relationship established between the metal effectively deposited and the one that should be deposited, according to the amount of electrical current applied.

This makes it necessary to avoid:

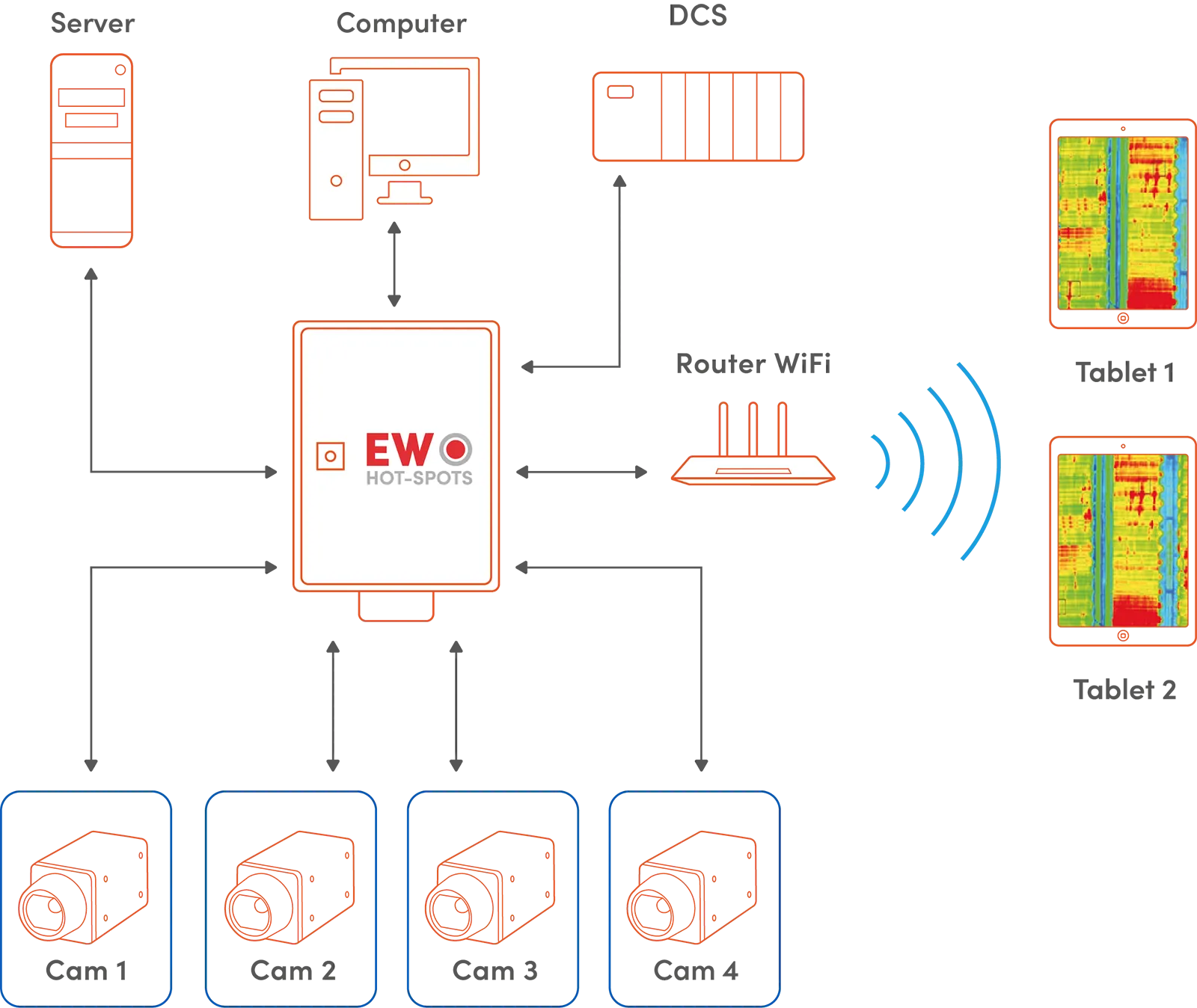

ECN Automation offers the HotSpot Monitor solution which uses thermographic vision technology and analytic algorithms to determine the temperature of each cell and abnormal / critical heating points that occur in this process. HotSpots Monitor works by using cameras on the plant structure to continuously monitor the temperatures in the electrolysis cells.

This provides an effective solution in detecting temperature outside the allowed range that may cause an eventual short circuit, benefiting the efficient consumption of the energy required in the process, as well as safety in the plant.

The system can be integrated through Modbus / TCP, with different communication protocols.

Modbus TCP/IP Ethernet/IP

Profibus DP

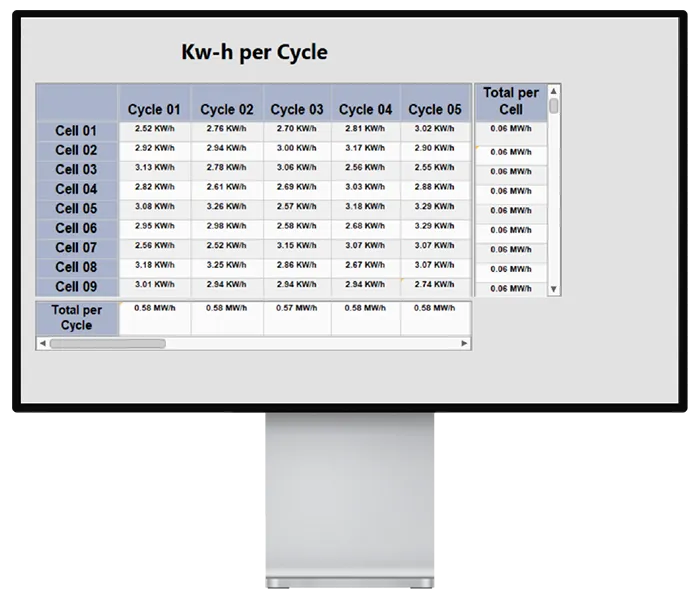

Database that stores temperature, energy consumption, date and time and thermographic images at the instant of detection. The information is displayed in a graphical, intuitive and interactive interface which provides tools to create reports quickly and easily with a single click.

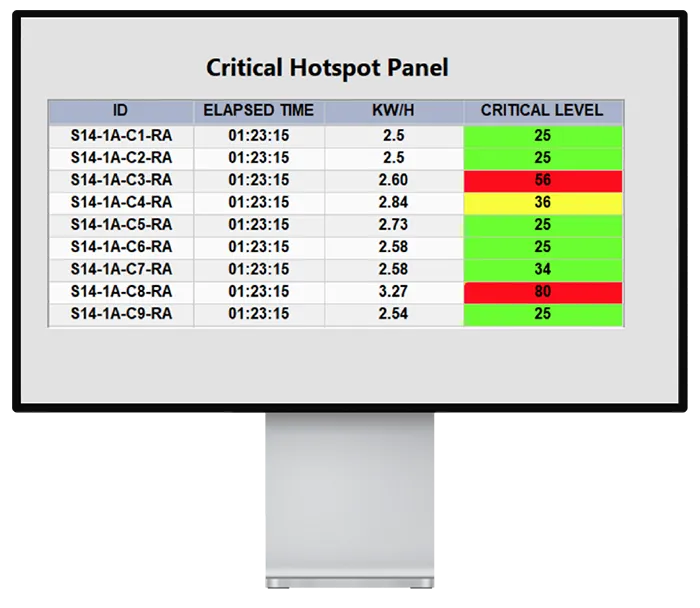

Interface that graphically displays the criticality levels according to the temperature and energy consumption of each hot spot, which allows the creation of different types of alarm according to the level detected.

Change alert of the cell’s interbus bars, through measuring their wear, based on its latest operating cycle’s hotspot history.