Safety Instrumented Systems (IEC 61511).

Process safety is assessed at SIL levels according to the IEC 61511 Standard. A SIL Safety Integrity Level always refers to a function instrumented safety (FIS).

A SIS (Safety Instrumented System) is composed of several FIS and will apply a SIL for each one, in these terms the SIL will be the measure of response to the demand that the FIS has or its ability to respond to bring the process to a state insurance on demand.

SILs range from SIL 1 to SIL 4, the former being the mildest and the latter being the most rigorous and reducing the risk to a greater extent.

The Safety Instrumented System, SIS, is made up of one or several Function Integrated Safeties, FIS, the Comprehensive Safety Level, SIL, of the SIS will be the highest or most rigorous and each FIS mitigates a different risk of the process.

Safety Integrity Level (SIL)

| SIL | Probability of fail on demand (PFD) | Risk reduction factor (1/PFD) | Safety availability (1/PFD) |

| 4 | >0.00001 a <0.0001 | >10,000 a <100,000 | >99.99 a <99.999 |

| 3 | >0.0001 a <0.001 | >1,000 a <10,000 | >99.9 a <99.99 |

| 2 | >0.001 a <0.01 | >100 a <1,000 | >99 a <99.9 |

| 1 | >0.01 a <0.1 | >10 a <100 | >90 a <99 |

ECN Automation functional safety solutions

SIL 2 safety level control systems

Industrial processing plants have, due to the substances they handle, an inherent risk; This risk must be systematically reduced by applying the layers of protection (LOPA) that includes the design of the plant, control system, operator intervention, Safety Instrumented System (SIS), Gas and Fire system, and the intervention of the city protection protocols.

In the design of the Industrial plant, the current Country Standards are followed, which establish the minimum acceptable requirements to guarantee the safety of the workers and the community, distances between tanks, dikes, discharge collection tanks, the risk analysis gives us the level of integrity that the SIS must have, for projects with integrity level SIL 2 we apply the solution with Rockwell ControlLogix with TÜV Certificate.

Common applications of SIL 2 are:

SIL 2 level architecture

Safety system based on modules level SIL 2 AADVance

Architecture-based safety system with redundancy

Emergency stop system

Faced with a condition that goes out of the safe range indicated by a variable such as the level of a tank or the pressure of a reactor or the temperature of a tank, among others, safety management can be immediate or sequential shutdown of the process, this is an example of a safety instrumented system, this SIS is also composed of input elements, logic and output controllers in compliance with IEC 61508 and the realization of the project in accordance with IEC 61511. The risk analysis of the plant indicates if the safety system is necessary and the SIL level that applies.

Depending on the area in which it is used, the emergency stop system applies the specific standards IEC 61511 for the process industry, IEC 62061 for machine safety, ISO 13850 for machine safety in the European system and for the design and manufacture of switches the IEC 60947 Standard.

Overfill protection

The overfill protection system consists of monitoring the tank level above the operating ranges of the control system and has priority over it, in such a way that it commands the actuation of valves, pumps and emergency devices to avoid a spill. In this way, avoid damage to people, infrastructure or the environment.

Overfill protection system

Combustion control

To have efficient and safe combustion control we need instrument, controller and actuator reliability. Certified to NFPA 85, NFPA 86, NFPA 87, UL and FM 06 standards.

Combustion control systems

Combustion control applications

Combustion control includes any machine that uses a burner, the main applications are:

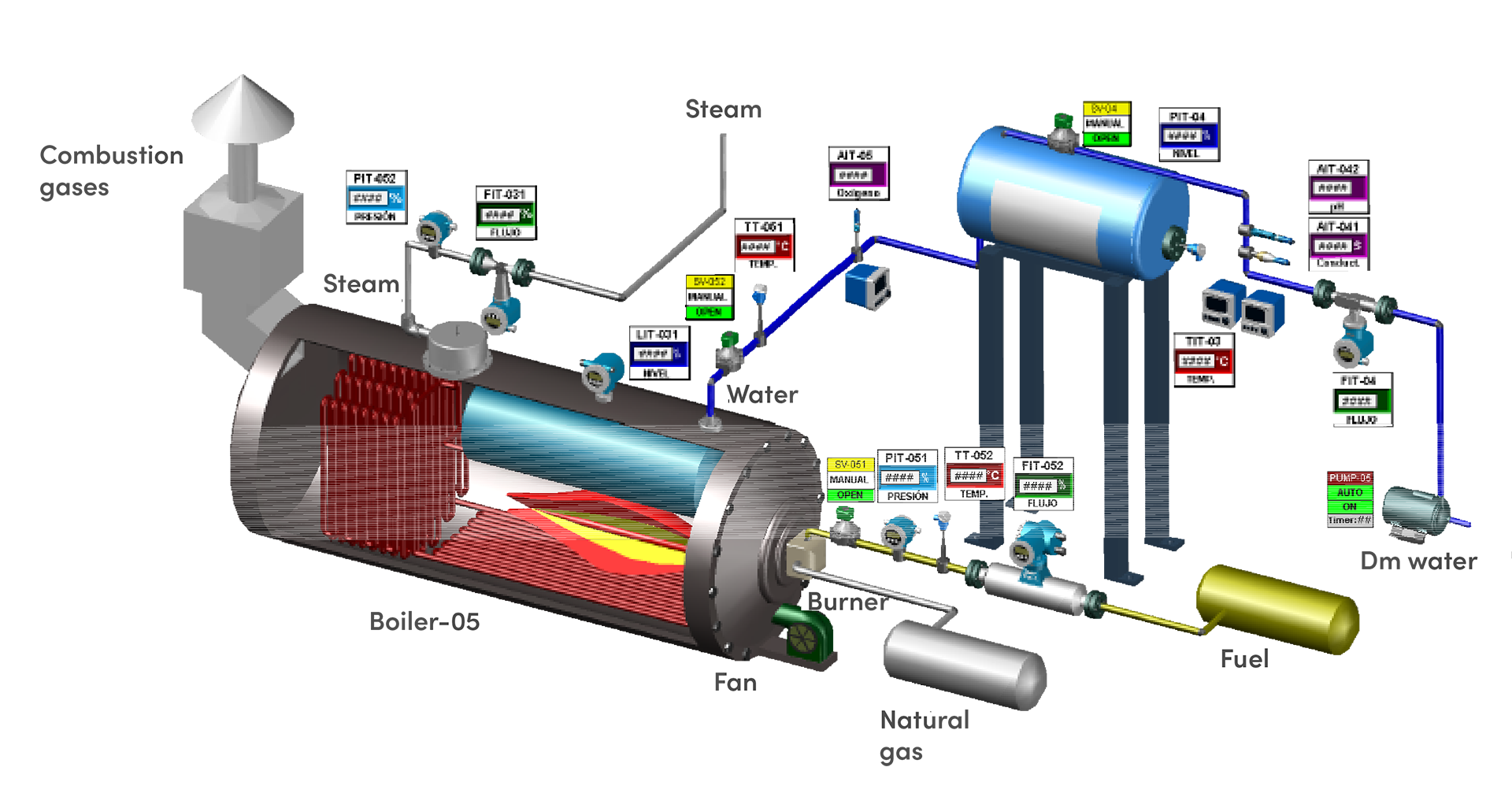

The variables to be monitored for the operation and efficiency of the boiler are represented in the image:

INCLUDES:

Steam flow

Steam pressure

Feed water level and flow

Inlet water conductivity

Combustion analysis

O2

Emissions analysis

CO2

NOx

CO

HC

SIL 3 safety system

Using the pre-engineered OptiSIS TM system that can help ease implementation and reduce delivery times for small and medium process applications. This includes oil and gas, chemical and petrochemical plants with outdated process safety systems that do not meet standards or can no longer be maintained.

It is designed for 50 or 100 point I/O safety instrumented system applications, including emergency shutdown systems (ESD), burner management systems (BMS), and boiler pressure.

Rockwell OptiSIS™

Prefabricated and customized safety control panel. With configurable safety functions according to the cause-effect matrix of the risk analysis.

OptiSIS 100 E/S