Machine Safety (ISO 13849)

With TÜV certification, ECN Automation develops machine safety projects such as palletizers, depalletizers, fillers, bottle washing machines, conveyors, among others; delivering reliable projects complying with all the requirements according to the norm, necessary according to the risk analysis of each machine.

Scope

Applications

Safety project with installation of perimeter guards with interlocks and light curtains with controllers and instrumentation according to ISO 13849.

13.48.33.png)

Machine safety norms

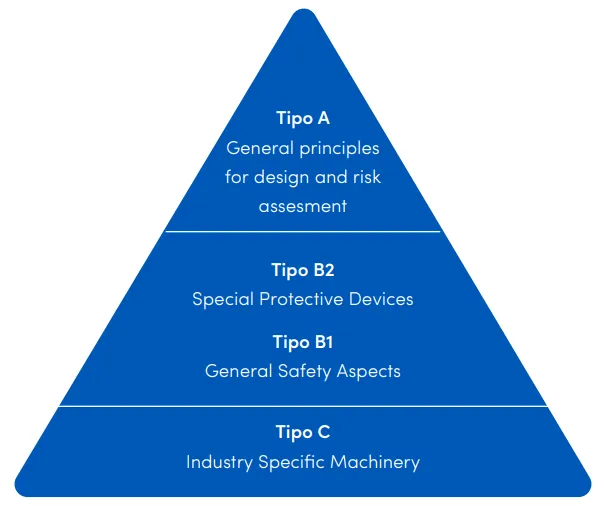

The hierarchy of safety standards

Safety standards are structured systematically and hierarchically, to exclude different requirements for comparable hazards or similar risks or to avoid recurrences:

Type A safety standard

Fundamental standards related to general safety guidelines, referred to all machines in the same or a similar way. e. g. risk assessment.

Type B1 safety standard

Group of standards referred to general safety features. (e. g. safe distance, electrical safety, proximity speed/subjection).

Type B2 safety standard

Group of standards reffered to special protection devices that can be used with machines. (e. g. Emergency shutdown devices, mesh lights, two-hand control devices).

Type C safety standard

Group of standards of a specific industry which establish defined requirements and safety measures.

ISO 12100:2010 Definitions

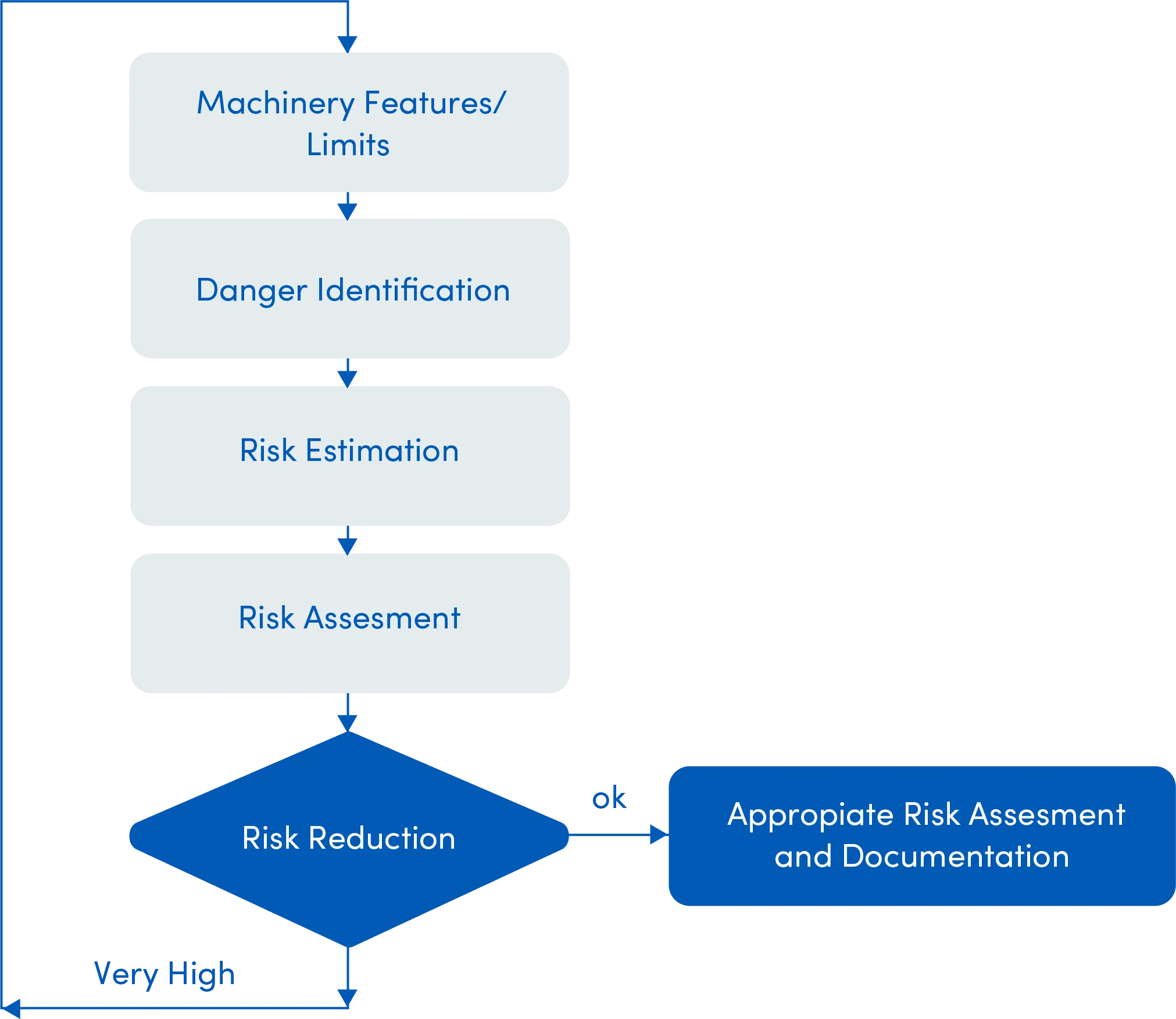

Risk Assessment

Global process which involves an analysis and risk assessment, typically a team effort.

Adequate risk reduction

Risk reduction based on safety norms rather than technology application criteria.

Evaluation and risk reduction strategy (ISO 12100)

Characteristics and limitations of machinery

The main objective of this step is to have a clear definition of:

Machine’s functions (based on the machine)

Machinery can be described in terms of its different parts, mechanisms or functionalities based on its construction, such as:

The use of machinery can be described in terms of associated tasks to its designed use and the reasonable foreseeable misuse of the machinery.