Fire & Gas Systems (NFPA, UL, FM, NOM)

The importance of preventing fires and hazardous gas leaks relies on preserving human life and looking after assets. At ECN Automation we have plenty of experience in fire detection and suppression, as well as hazardous gas detection for different industries.

For the implementation of this kind of projects we evaluate the necessary safety elements through risk assessment to comply with the norms:

Always valuating the importance of safety in fire & gas projects.

15.30.44.png)

15.20.37.png)

14.28.39.png)

Foam and water suppression system applications.

Toxic gas detection and alarm

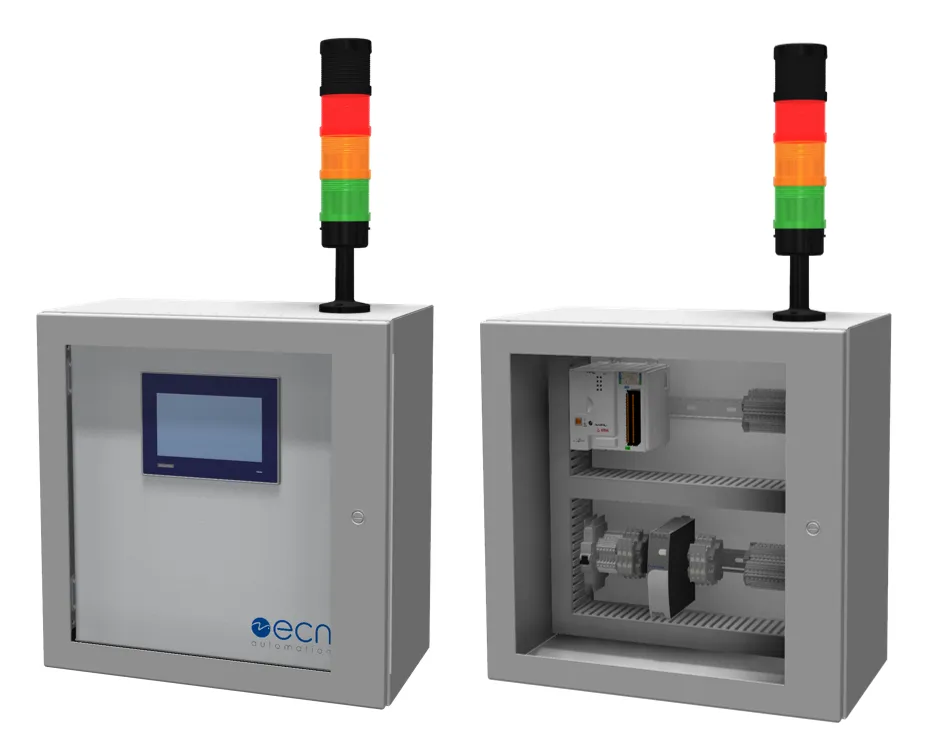

Gas Monitor

A gas detection system implementation is the best way to create a safe environment for people in the industry, preventing the existence of toxic gas concentration, explosive gases, and even an environment where the la of oxygen can be at risk in the work place.

Explosive gases and fire detection and alarm

Fire & Gas systems in the industry are the key for human and infrastructure safety; we have the experience to develop projects under national and international norms, also providing support in audits performed by regulating entities.

For the implementation of gas systems, our personnel uses norms NOM-002 and NOM-010 as guideline, besides IEC and/or ATEX standards applicable to the needed solution, through a risk assessment engineering therefore being able to prevent, avoid or control an unwanted condition.

13.56.39.png)

Application

Fire control panel

FM200 Clean gas tanks

Traffic light sign system in electrical room

Suppression system using inert gas in electrical conduits

Fire extinction

Our staff is certified in NFPA 72 and NOM-002-STPS, experienced to specify the adequate solution for every area in your plant, based on fire mitigation and control safety norms.

Fire extinction systems:

Areas:

14.24.57.png)

Application

Hydrant Network

Foam

Fire Sprinkler System

Clean Agent

Fire & Gas Integrated Solutions

Early detection and fire alarm is the first step in avoiding human and material damage; in strict compliance of current norms the best prevention is possible.

Fire & Gas and integrated project consists of:

Evaluation

Design

Implementation

Fire extinction methods

Fuel cut off

Installation of automatic fuel cut off valves at the moment of smoke or fire detection in the protected area.

Suffocation (Oxygen displacement)

Clean Agent system installation in office areas (site) or foam systems in fuel tanks.

Inhibition (Chain reaction cut off)

Powder extinguisher installed to be used manually or automatically in the protected area.

Refrigeration (Heat reduction)

Installation of an automatic or semi-automatic system through water based sprinklers or hydrants.

The main principle in which the design of fire protection is based is that, unless otherwise stated, most risks can be extinguished with extinguishing agents if the application is correct. A quick guideline for firefighting systems is the following chart:

Fire Type

|

Extinguishing Agent |

Class A |

Class B |

Class C |

Class D |

Class E Electric Voltage |

Class K |

|---|---|---|---|---|---|---|

|

Jet Water |

Good |

Null |

Null |

Null |

Highly Dangerous |

Null |

|

Pulverized water |

Excellent |

Aceptable |

Null |

Null |

Dangerous |

Null |

|

Physical Foam |

Good |

Good |

Null |

Null |

Dangerous |

Null |

|

Dry Powder |

Null |

Excellent |

Good |

Null |

Good |

Null |

|

Polyvalent Powder |

Good |

Good |

Good |

Null |

Good |

Null |

|

Powder for metals |

Null |

Null |

Null |

Excellent |

Null |

Null |

|

CO2 |

Good |

Good |

Null |

Null |

Good |

Null |

|

Potassium Acetate |

Null |

Null |

Null |

Null |

Null |

Excellent |

Acceptable*1 for liquid fuels non water soluble

Good*1 do not use with water soluble liquids

Good*2 (for voltage below 1000V)

Fire & Gas Integrated Solutions

Fire & Gas integrated solution include: