Integrated architecture

Integrated architecture is a concept that brings together the complete solution for the automation of a process, a plant area or a complete area, includes the complete solution of automation hardware and components, motor control center, variable speed drives, communication networks, data center and control room operating stations.

ECN Automation is certified as a solution partner to design and develop automation, safety and process information solutions based on Rockwell Automation technology.

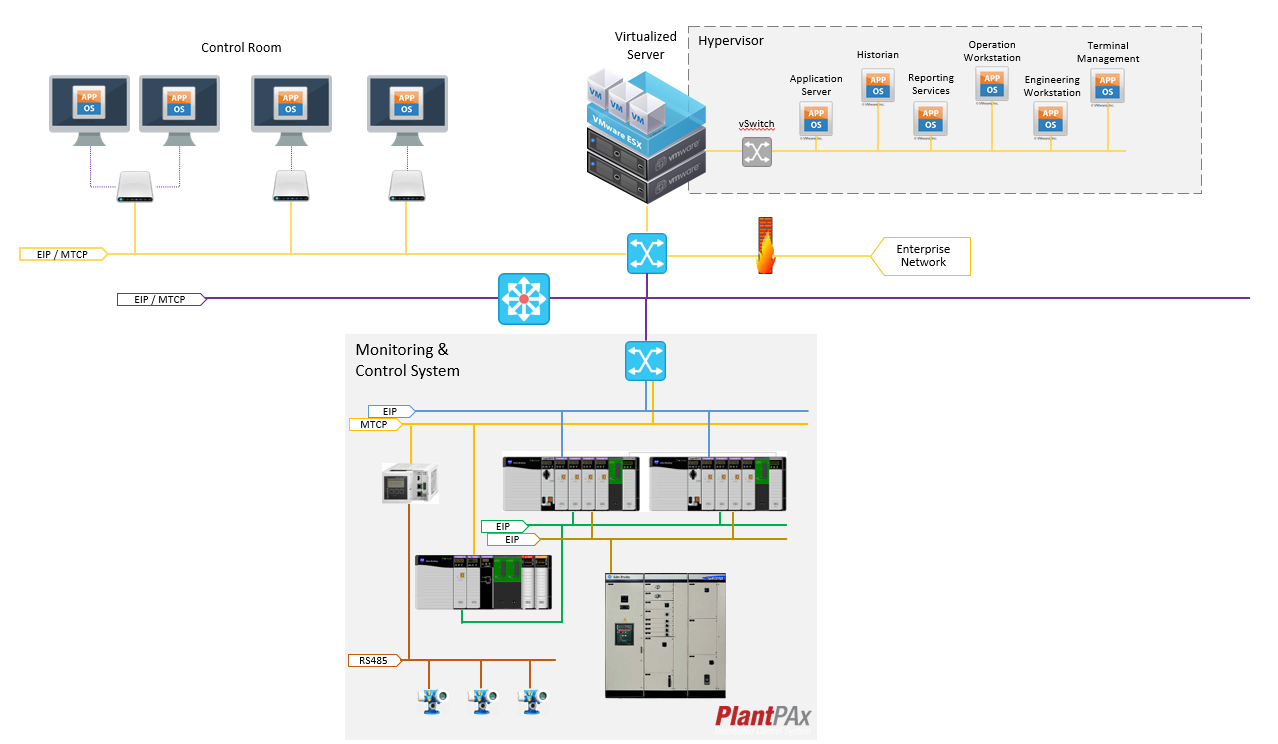

Integrated architecture example

Logix PLC Platform

The Logix platform includes ControlLogix, CompactLogix and GuardLogix controllers. These PLCs are used for process automation and safety in plant areas, complete plants or machines.

The programming and design of applications in the Logix family is done with Studio 5000 software from Design Suite.

At ECN Automation we have carried out more than 2,500 automation projects on Rockwell platforms. Our engineers are constantly updated in this technology, which ensures a perfectly dimensioned system for the application, optimal programming for the use of hardware and software resources, obtaining a system with the best performance for the productivity and safety of your process.

.png)

ControlLogix Large Process Automation

.png)

ControlLogix SIL 2 Process Safety

.png)

CompactLogix MID Process Automatio

Compact GuardLogix Machine Safety

ControlLogix

The ControlLogix system is designed for automation of large processes such as plant sections or complete plants; For discrete, sequential, continuous control, complex applications and advanced control.

A simple ControlLogix system consists of a separate controller and I/O modules in a chassis. For a more complete system, the following arrangements can be made:

ControlLogix SIL 2

The ControlLogix SIL 2 system is designed for process automation based on a comprehensive level of safety (SIL) for critical processes in which the degree of risk must be reduced through the safety function.

Applications in:

CompactLogix

The CompactLogix system is designed for the automation of specific processes in a plant or for the operation of machines for discrete, sequential and continuous control.

GuardLogix

The GuardLogix system is designed for the safe operation of machinery, safeguarding the interaction of the operator, maintenance personnel and personnel in transit around it.

Graphical operating interface Panel View

The operating interfaces are graphic screens designed for factory assembly through which the operator views the process, monitors conditions and performs operating actions. Depending on the process to interact, be it a machine directly, a complete production area, or the capacities of graphics, memory or screen size, there are several versions of Panel View:

PanelView Family

Programming platform Design Suite

Software suite for programming, configuration, design and emulation of the Rockwell Automation Logix and Panel View platform.

Design Suite components:

Studio 5000 Logix Designer

Software suite for programming, configuration, design and emulation of the Rockwell Automation Logix and Panel View platform.

20.44.42.webp)

Studio 5000 View Designer

It is the design and programming environment for the family of operator terminals, Panel View, at all levels, contains libraries that streamline and standardize development.

20.44.52.webp)

Studio 5000 Architect

It is the environment you need to kickstart the initial build of your system for your control and display applications.

20.44.59.webp)

Studio 5000 Application code manager

It is a tool that allows more efficient project development with reusable code libraries.

20.46.27.webp)

Studio 5000 Logix Emulate

It is a tool that allows simulation to be able to validate, test and optimize the application code regardless of the hardware.

20.46.40.webp)

Studio 5000 Simulate Interface

It is a tool that allows you to connect controllers, physical or emulated, with simulation and modeling tools to allow virtual commissioning and model-based design.

20.46.49.webp)

Switches ethernet industrial Stratix

EtherNet / IP networking solutions provide plant-wide networking systems using open industry standard networking technologies. They enable real-time information and control in discrete, continuous, batch, security, drive, motion, and high availability applications. The EtherNet / IP network connects devices such as motor starters and sensors to HMI devices and controllers. Supports industrial and non-industrial communications on a common network infrastructure.

Stratix 2000

They are ideal for small control networks. These small switches are industrial grade, require no configuration and use non-redundant UTP single cable connections and do not have fiber optic ports.

Stratix 2500

Switches for small control applications where some configuration is required.

9.41.24.webp)

Stratix 5400/5410

They enable Layer 2 switching and Layer 3 routing, using a combination of Gigabit Ethernet (GE) with Power over Ethernet (PoE), GE fiber ports, and Ten G. Additionally, this switch offers DLR with three-ring support, which allows more devices to be connected at the cell / area zone level for greater flexibility in network design such as network translators (NAT).

9.43.04.webp)

9.43.12.webp)

Stratix 5700

Manageable Layer 2 switches for medium-sized applications, allow device integration up to the connection to a higher layer.

9.44.24.webp)

9.50.50.webp)

Stratix 5800

Industrial managed Ethernet switch that offers gigabit performance, supports a wide variety of modular designs that support copper, fiber, and Poe expansion modules, and is available with Layer 2 or Layer 3 routing firmware options.

Stratix 5950

Manageable Layer 2 or Layer 3 switch that combines multiple security functions with enhanced features in a single device to help protect your industrial automation infrastructure.

9.51.13.webp)

Stratix 8000

Modular Layer 3 Managed Switches using the current Cisco® Catalyst® switch architecture and feature set, along with powerful configuration tools, providing secure integration with the IT-level management network

9.51.03.webp)

IntelliCENTER® Motor Control Center

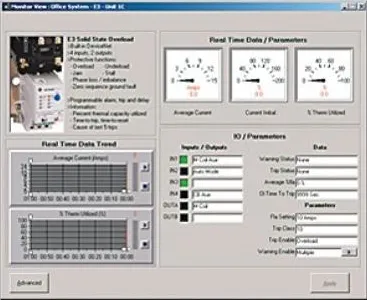

IntelliCENTER® software provides the ultimate window to your Motor Control Center (MCC). The software puts both real-time diagnostics and MCC documentation at your fingertips to maximize the performance of your MCC and related equipment.

Graphical views of individual MCC units display device data and allow you to quickly view critical status information. The Integration Wizard feature allows you to automatically create an I / O tree in the Studio 5000 environment or auto populate meter data in FactoryTalk® EnergyMetrixTM using information from the IntelliCENTER software. IntelliCENTER® Energy provides automatic and preconfigured factoryTalk EnergyMetrix configuration for intelligent motor control devices in the motor control center.

Characteristics:

CenterLine 2500 IEC

12.01.11.webp)

CenterLine 2100 NEMA

Configuration Software

PowerFlex variable speed drives

PowerFlex drives provide ease of use, application flexibility, and high performance. They include multiple hardware and control options, as well as built-in security features. These drives are ideal for a wide variety of motor control applications, including pumps, fans, and conveyors. With dual port EtherNet / IP communication for ring, line and star topology. Plus Device Level Ring (DLR) functionality to provide fault tolerant connectivity and high drive availability.

General description:

Compact-class type AC low voltage drives

Architecture-class low voltage AC drives

SMC Flex Solid State Starter

SMC Flex soft starters are available with a current range from 5 to 1250 A. They offer integrated bypass and flexible communications with advanced protection, diagnostics and performance.

General description:

Solid State Starter SMC Flex