Innovation Suite

FactoryTalk® Innovation Suite, powered by PTC, is a comprehensive portfolio that brings analytics, machine learning, Industrial Internet of Things (IIoT), and Augmented Reality (AR) to industrial operations. This powerful platform simplifies the way your business manages data and makes it easy for everyone to access, understand, and take advantage of the information they need to make decisions.

Innovation Suite collects and consolidates information technology (IT) with operational technology (OT) from your existing equipment and systems, so you can make data-driven decisions that align with your exact needs. Your workforce can easily find the data they need to drive real improvements.

Components:

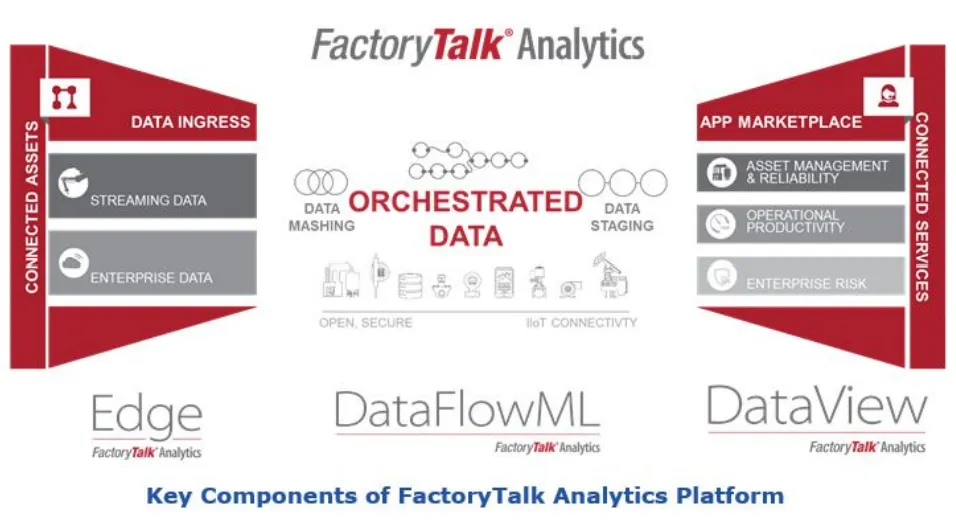

Factorytalk Analytics

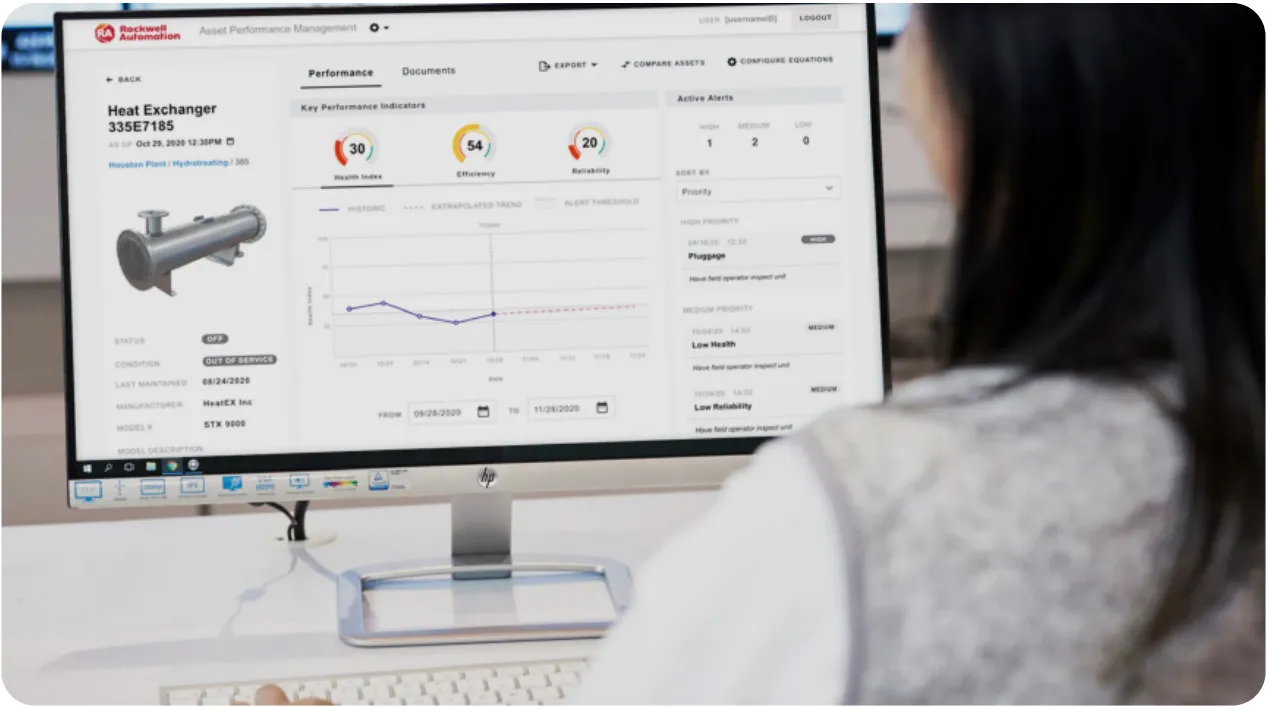

FactoryTalk® AnalyticsTM provides industrial manufacturing professionals with a full spectrum of descriptive to prescriptive analytical solutions to achieve results such as improving Overall Equipment Effectiveness (OEE), reducing downtime, and improving quality or processes performance.

Customers benefit from a complete solution, from building a solid industrial data management foundation to single panel operation views; Collaborative data mashups to create and deploy self-service machine learning or analytical models on the controller, Edge, or in the cloud. With visual tools, the ability to put data science in the hands of domain experts, and innovative analytical templates to drive proven results, the entire machine learning workflow is supported from data to value to address predictive maintenance, anomaly detection and use of model process control.

FactoryTalk Analytics also seamlessly integrates with the Innovation Suite’s Augmented Reality and MES solutions to bring actionable insights to the shop floor and streamline supply chain operations at the enterprise level.

Thinworx IoT Platform

As part of the Innovation Suite, the ThingWorx IoT platform connects devices, applications, and data sources across your enterprise, providing a single source to collect, add, and enable secure access to industrial operations data. Its design allows you to connect, manage, monitor and control various automation devices and software applications through an intuitive user interface.

Vuforia Augmented Reality

Train your workers to perform better and avoid safety and compliance risks by giving them easy access to the information they need. Use industrial Augmented Reality (AR) to improve workforce productivity, efficiency, and customer satisfaction with real-time step-by-step work instructions.

Vuforia AR solutions allow you to create and deliver easily consumable instructions with new or existing media content / capture, 2D and 3D content, sequences, IoT data, and annotations in real time in shared environments.

Compatible Wearables:

Each Vuforia solution is optimized for specific capabilities and use cases.

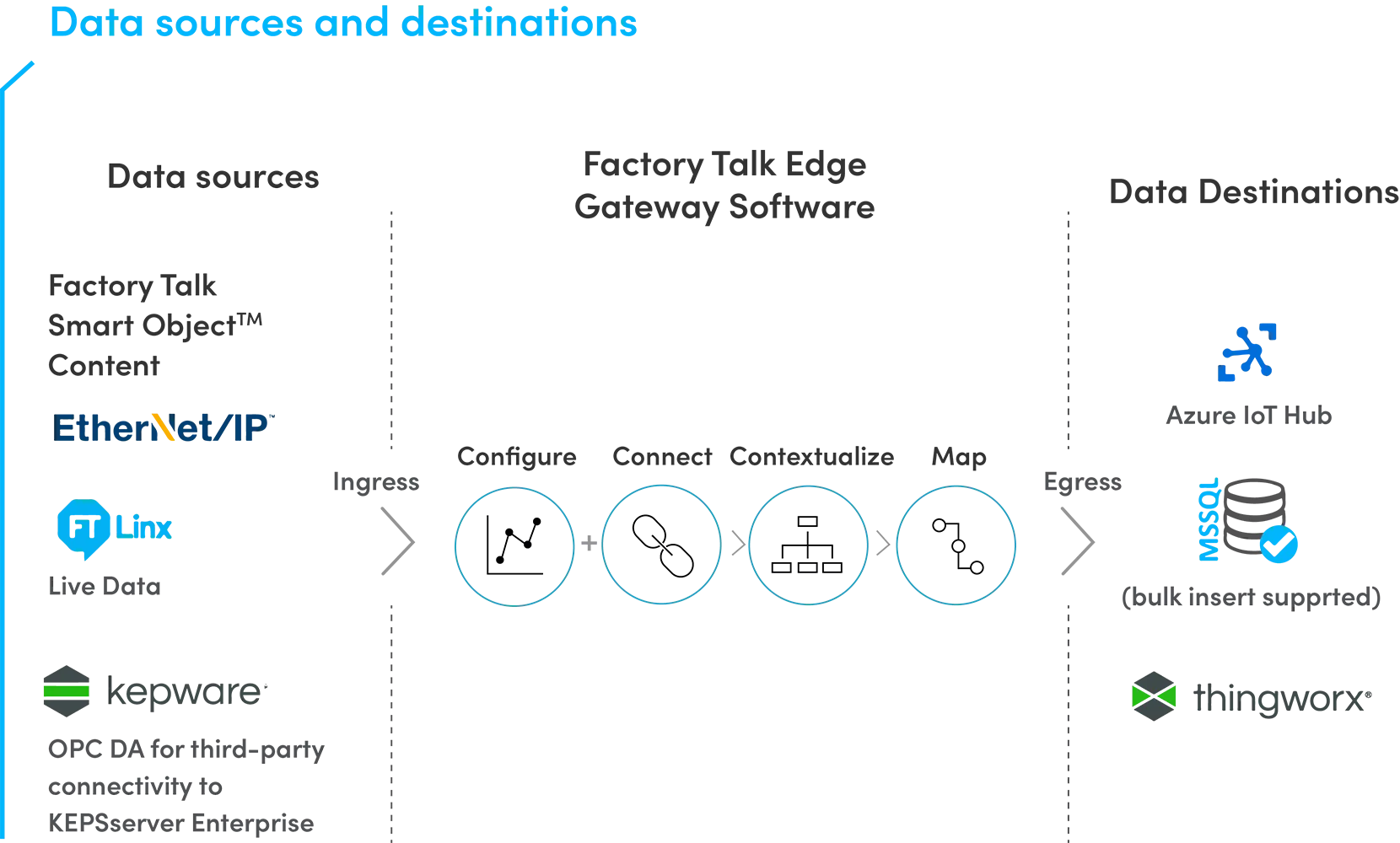

FactoryTalk Edge Gateway

FactoryTalk Edge Gateway software unifies data from industrial sources and automation or control systems. It integrates with a variety of cloud, IoT, and big data applications, including ThingWorx, Microsoft Azure IoT Hub, Microsoft SQL, and more. It also uses OPC-DA, the automation industry interoperability standard, to access KEPServer Enterprise data for third-party connectivity. This maximizes operational insights and provides a 360-degree view of your business, simplifying and automating data ingestion in a single integration solution for IT applications.

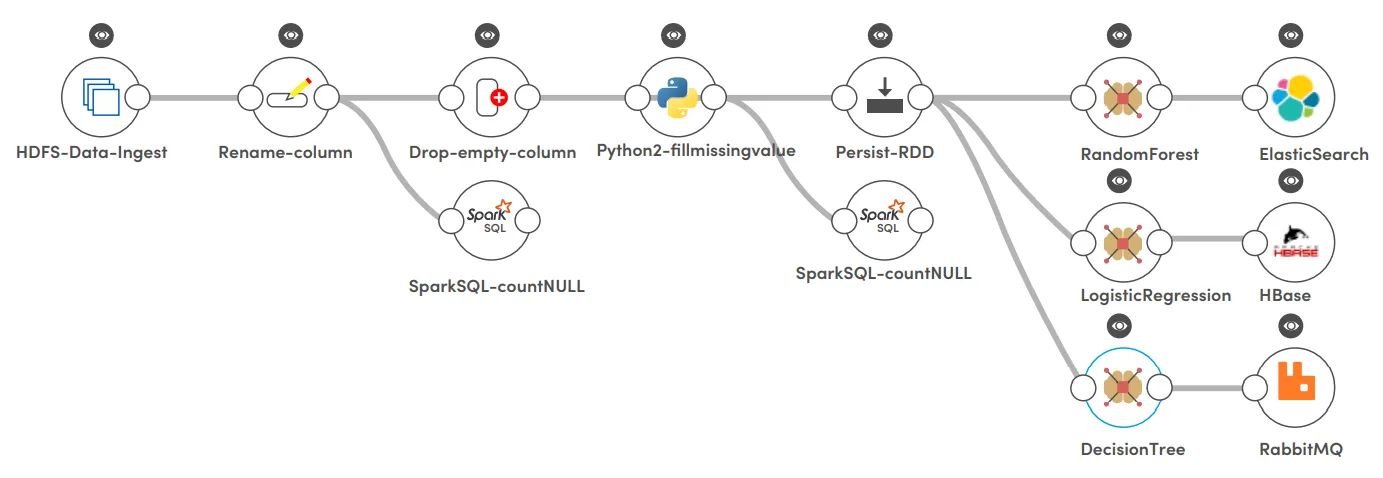

FactoryTalk Analytics DataFlow ML

FactoryTalk® Analytics TM DataFlowML is a big data analytics and ML (Machine Learning) platform that enables data scientists to visually build, train, implement, score, and monitor ML models. With the explosion of data transfer and large-scale manufacturing, data scientists are constantly expected to create smart applications and discover enterprise-level insights at the site and plants.

To ensure a faster path to enterprise-scale innovation, they must be enabled to create and implement analytics solutions, including machine learning models in big data, and reuse them across multiple locations.

To do this, data scientists need an open, standardized, secure, and enterprise-grade analytics platform where they can collaboratively manage the entire model lifecycle in a centralized IT environment. By doing this, they should be able to combine data from multiple sources, take advantage of out-of-the-box open-source machine learning libraries for faster model building, and take advantage of pre-built input and output data connectors for various ITs or OT data sources.

FactoryTalk Analytics Edge ML

FactoryTalk® AnalyticsTM Edge ML enables OT professionals on the plant floor to harness the power of machine learning and visual data pipelines, while fully applying their deep discrete or process manufacturing expertise to their advantage. FactoryTalk Analytics Edge ML provides ease of use for connecting data sources, data pipelines, and the flexibility to bring your own model, right to the industrial edge.

As a result, OT professionals can continually improve operations by implementing models that help detect defects prior to packaging and optimize on-site production or process parameters through event-based controller feedback at low latencies. All of this is accomplished by using space-saving hardware such as computing modules, gateways, and headless industrial PCs.