SO2 emission reduction at thermal power plants

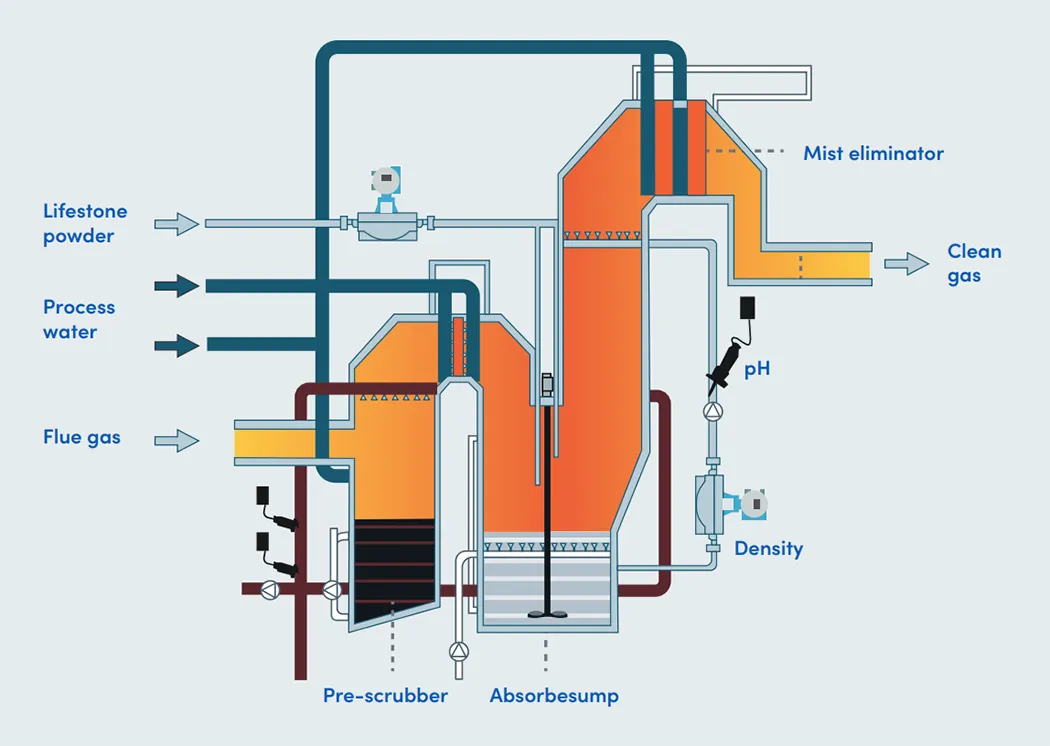

According with regulations regarding sulfur level in emission gases, thermal power plants use desulfurization technology, developing the following process: gases coming from coal combustion in the boiler.

Thanks to this desulfurization process, SO2 reduces 95%

As a result of the process, a gypsum layer is found at the bottom of the absorber.

The main parameters to control in this process are pH, density measurement and solids’ content in suspension. pH measuring requires an automatic measuring system able to adapt to difficult process conditions.

Measuring gypsum’s suspension density is important for the efficiency of combustion gases depurators. If a certain concentration is obtained, suspension will be set to ground. Density measurement can be done by the Promass Coriolis mass flow meter.

pH measuring requires of an ideal automatic measuring system able to adapt to difficult process conditions. At the flue gas desulfurization (FGD) plant, combustion gases are sprayed with a limestone suspension. Sulfur dioxide (SO2) in combustion gases reacts to limestone. A gypsum suspension is produced by injecting air. The FDG function is to achieve an optimal desulfurization effect, as well as a high quality gypsum.

Promass – Coriolis mass flow meter

Measure density and quantity with one device (two exit signals). Effective in aggressive and abrasive gypsum suspensions. Up to 0.0005 g/cm3 precision for a better desulfurization plant control.

Memosens –Digital pH sensor

A critical element in pH measurement is the electrode. Extremely low currents, high internal resistance in the electrode are a must aside from the high impedance link between the sensor/transmitter. Moisture presence can negatively affect pH measurement. Memosens technology revolutionizes data transfer by digitalizing values measured by the sensor. Data transfer from the pH sensor to the transmitter is done digitally via wireless (moist sensible) between sensor/transmitter. Memosens technology saves calibration/configuration data that can simplify planned maintenance

Completely automated pH measurement spots system and redox in all industries.

11.32.48.webp)