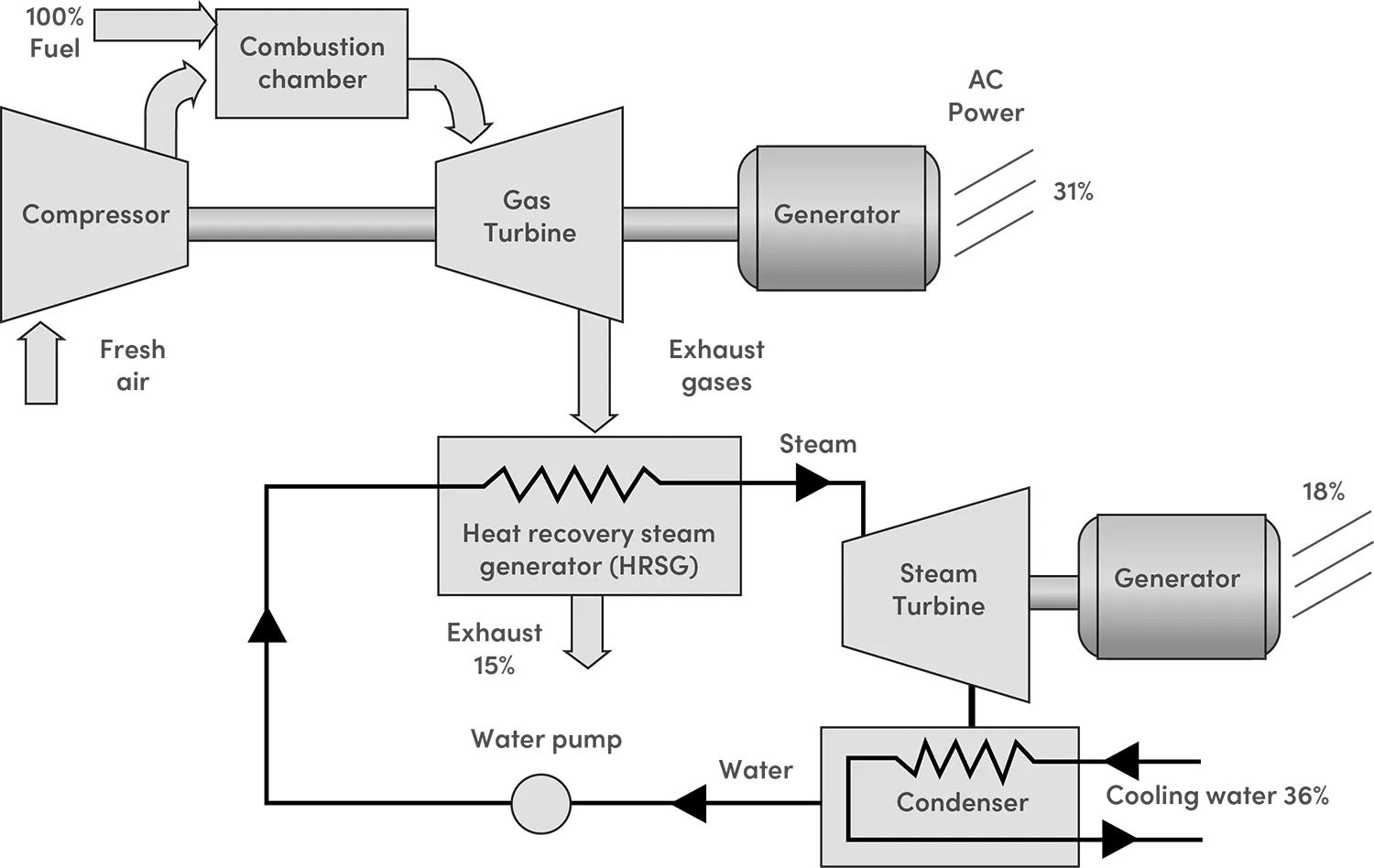

Combined cycle power plant

Combined cycle power plants transform natural gas thermal energy into electricity through the joint work of a gas turbine and a steam turbine. The process requires starting two consecutive processes: the Brayton cycle which corresponds to the conventional gas turbine and the Rankine cycle which operates with the steam turbine.

Combined cycle power plants are characteristic for being more flexible than conventional ones. This means it can operate at full load or partial load, up to a minimum of about 45% max power. They are also more efficient (more efficiency for a wider range of power) emissions are lower, cooling water use is less and save fuel energy. Last, they are built faster and need less space per square meter than other power plants which reduces the visual impact.

Combine-cycle power system

Combined-eyele power system with representative energy flows providing

a total efficiency of 49%

Compressor

Its function is to inject pressured air to achieve gas combustion and cooling of hot zones.

Combustion chamber

This is where natural gas (fuel) is mixed with pressured air, producing combustion.

Gas turbine

This is where gas expansion coming from the combustion chamber takes place. There are three or four expansion stages and gas temperature at entrance is about 1,400°C leaving the turbine at temperatures higher than 600°C.

Heat recovery steam generator

In this conventional boiler, heat coming from the gas turbine is taken advantage of in a water-seam cycle.

Steam turbine

This turbine is usually made of three bodies and is based in conventional technology. Having the gas turbine and steam turbine coupled to the same axis is common thus activating the same power generator.

Flow diagram of the Combined Cycle Power Plant process