Iron pelletizing

The iron ore concentrate as a final product of the mining exploitation is a powder, to continue the process in the production of steel it is necessary to agglomerate or pelletize this powder in a presentation of small homogeneous balls better known as pellets. These pellets are uniform in size and porous which improves blast furnace performance and prevents waste.

Benefits of agglomeration:

Topics:

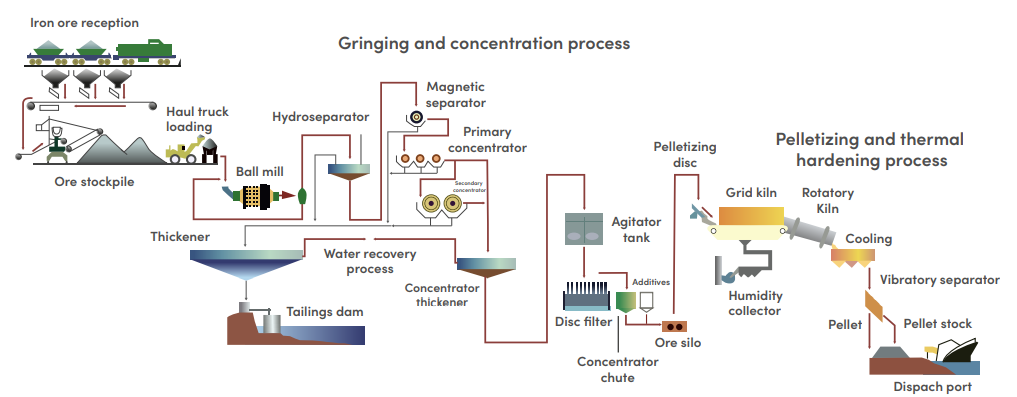

Process flow diagram

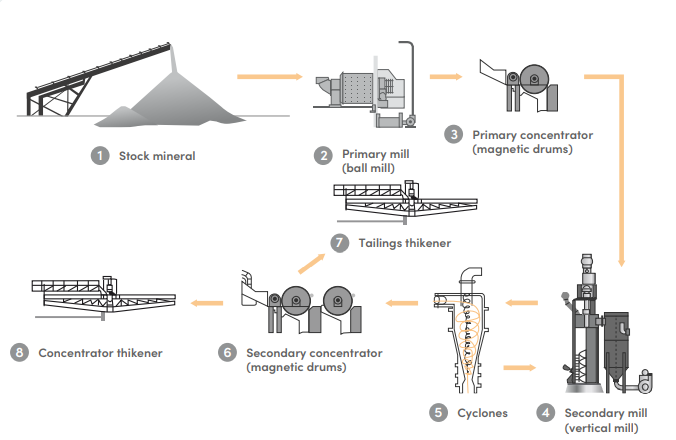

Wet grinding and classification

The pre-concentrate is transported from the storage piles to the grinding stage, which is made up of three processes lines.

Each line has a wet ball mill, in which the iron ore is reduced in size in order to expose the useful ore to a greater degree.

Magnetic concentration, filtering and balling (creation of the ball)

Magnetic Concentration

The magnetic separation of the mineral is generated, taking advantage of the ferromagnetic properties of iron in order to separate said mineral of various qualities. Then, the material enters a primary and a secondary magnetic concentrator, these concentrators are of high power, being able to attract minerals with weak ferromagnetic properties through magnets of high intensity and force.

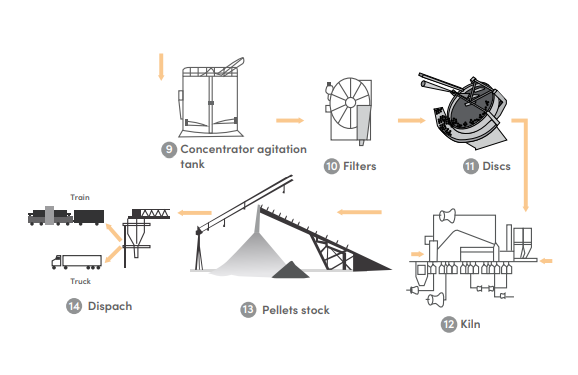

Filtering

The material resulting from the previous process is thickened and then is directed to the agitator tanks, these agitators are used to keep the solids in suspension and homogenized pulp, in such a way that it is ready to come into contact with the reagents to minimize flotation times. Then, the mineral from the agitator pond is taken to a disc filter, where the total percentage of water present is again reduced, obtaining the product called Pellet Feed, which feeds the Balling process to produce the pellet.

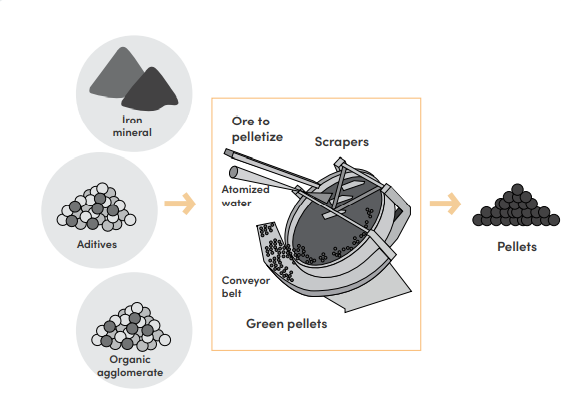

BallBallinging

The filtrate is mixed with an additive (limestone) in an amount according to the type of pellet to be produced and the mixture is fed and transformed into green pellets in the pelletizing discs where crude iron pellets are formed. These pellets are transported by conveyor belts to furnace at high temperatures, where they will be kiln.

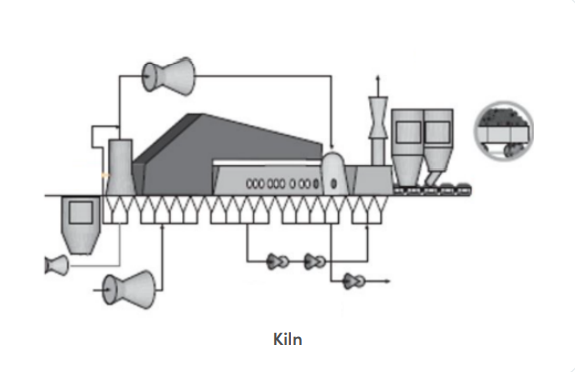

Thermal hardening and storage

The green pellets are dried and heated in a kiln up to a temperature of 2,012 °F. The pellets are heated to improve their mechanical characteristics, that is, resistance to pressure and abrasion index (resistance to transport conditions). They are then taken to the rotating kiln, where they are finally hardened at temperatures of approximately 2,372 °F and subsequently taken to a cooler. The cooled pellets are classified by size and go to storage in product fields where they are collected while waiting to be loaded onto transport ships.

Quality, size and resistance

Now, after manufacturing, we have to apply certain quality standards to the pellets. As a rule, the following parameters apply:

Size and granulometry:

It is carried out through an analysis of sieves, to know its granulometric distribution, pointing out to have the highest percentage between 3/8" and 5/8" (9 mm - 12 mm) and the lowest possible percentage less than 1/4 "(6.3 mm). Values greater than 85% between 3/8" and 5/8" are acceptable, as well as less than 3% in 1/4".

Cold pressure resistance (ASTM):

It is determined by subjecting the pellets individually to an increasing compression force generated by two plates until the pellet breaks, at which point the maximum force (Kg) in which it is destroyed is measured, so that the test is representative, it takes the average of 20 pellets for each determination. Average values above 200 Kg/pellet are acceptable.

Tumbler degradation Index (ASTM):

It measures the behavior of the pellet during handling and abrasion; the test is carried out in a drum, for the case of the ASTM standard it is 0.914 m in diameter by 0.457 m in length with two inner flanges of 50 mm in height at 25 RPM 11.3 Kg of sampled material are tested, it is subjected to 200 revolutions; the result is reported as the percentage fraction greater than 6.3 mm and less than 0.6 mm.

Other quality parameters: