Hot Rolling

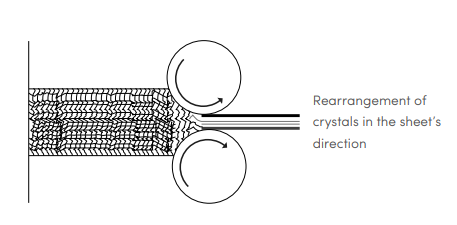

The steel sheet is one of the most used products in the industry to produce different goods. The rolling process takes advantage of the malleable characteristic of metals, thus a steel bar goes through different stages of rollers that deform it to an increasingly smaller thickness by compression force this process can be carried out cold or hot obtaining a different product in each case.

In the hot rolling process, the steel bar raises its temperature up to 2192 °F since its ductility and malleability increase, therefore, the process of reducing the thickness of the sheet is easier.

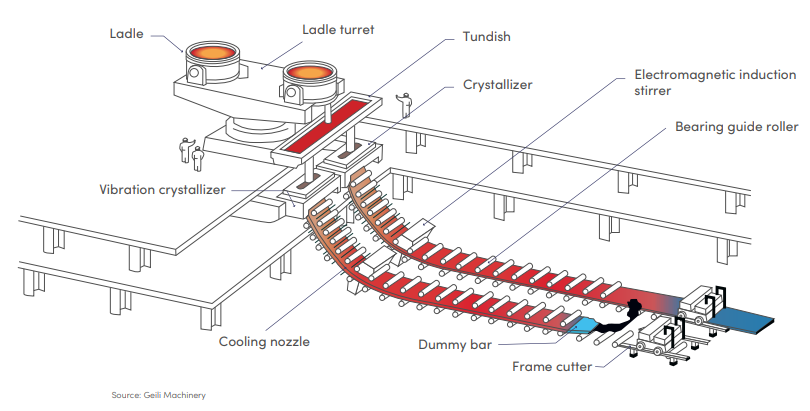

Continuous casting

The continuous casting process consists of transforming the steel from its liquid state coming out of the foundry to the final product.

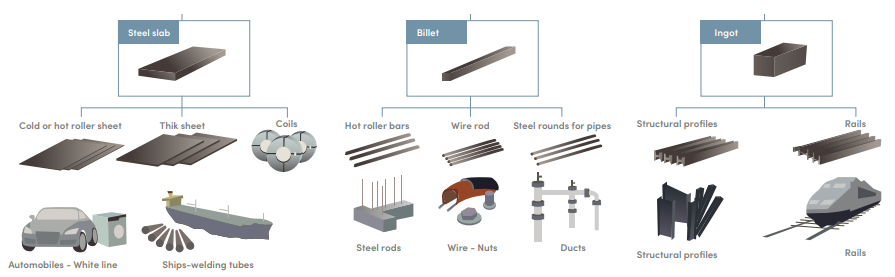

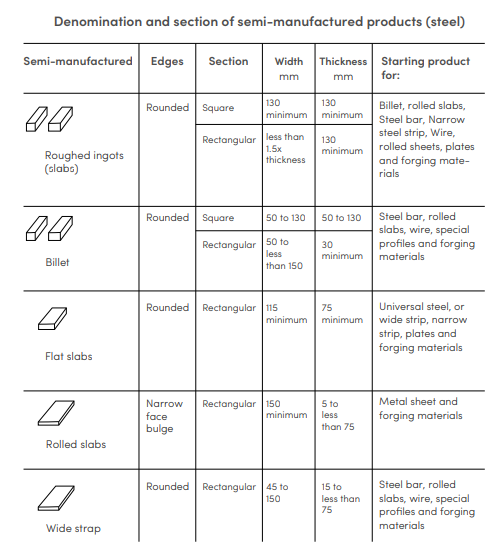

Continuous casting products

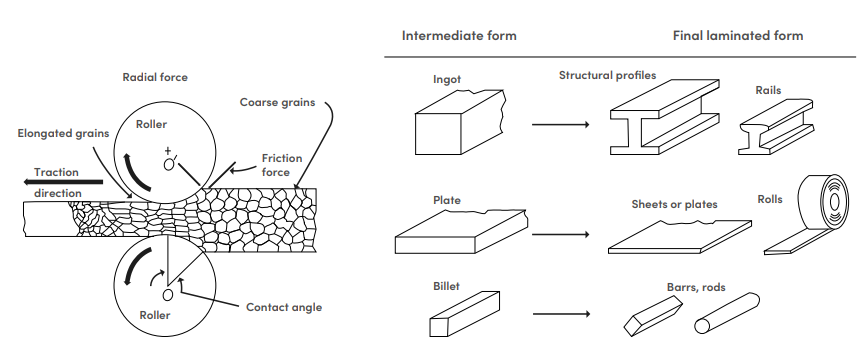

Rolling processes

Rolling is a deformation process in which the metal passes between two rollers that exert compression force and pull the material while decreasing its thickness.

Features of hot rolling:

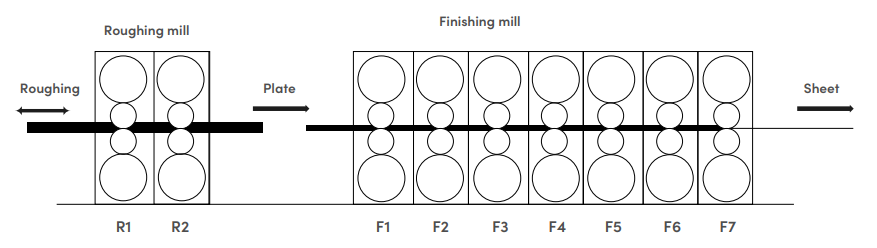

Roughing and Finishing

Roughing:

• First phase of the process in which the 200 mm thick slab enters and is reduced to 35 mm with two roughing frames

Finish:

• Subsequently, it goes to the finishing racks for a reduction of up to 2mm sheet

Roughing, forging and finishing

1. Heating and rough rolling of the ingots obtained in the casting to transform them into blooms and slabs.

2. Reheating followed by forging rolling and finishing of the blooms and slabs obtained in the previous step or in a continuous casting machine to obtain, respectively, longs or flats.

In hot rolling, the ductility of steel is taken advantage of, that is, its deformation capacity, which is much greater the higher its temperature.

Basic characteristics of hot rolling