Avoid unscheduled shutdowns in cooling towers

Catastrophic failure of a cooling tower can have serious consequences for plant operations, safety hazards, downtime and costly repairs. Common causes of cooling tower failure is the misalignment or imbalance of a fan.

Studies have shown that the most common cooling tower component failures were related to the motor (60%), gearbox (30%), fan (2%) and other (8%). More specifically, motor failures can be caused by motor imbalance, shaft misalignment, rotor bar defects, bearing defects, and improper base mounting.

Types of cooling towers

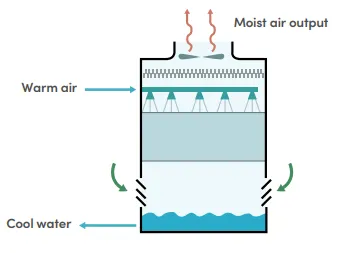

Counterflow Cooling Tower

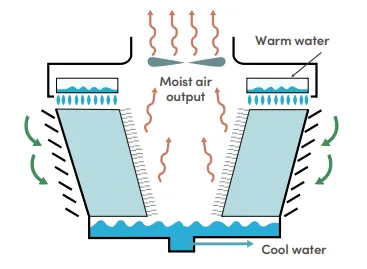

Cross Flow Cooling Tower

Solution

Detection of operational conditions through vibration measurement system.

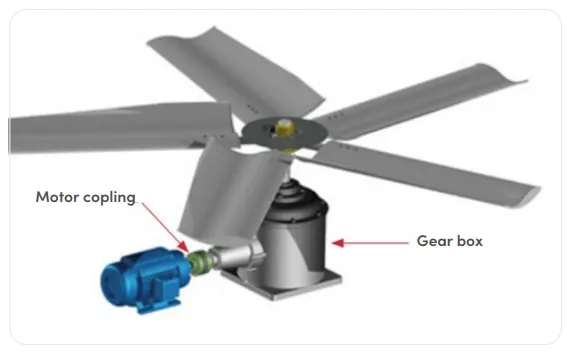

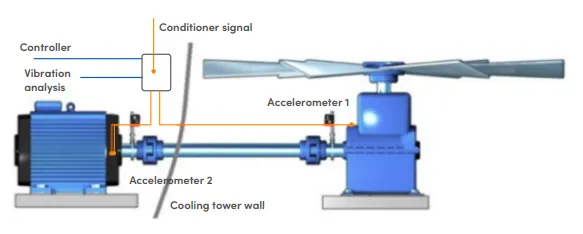

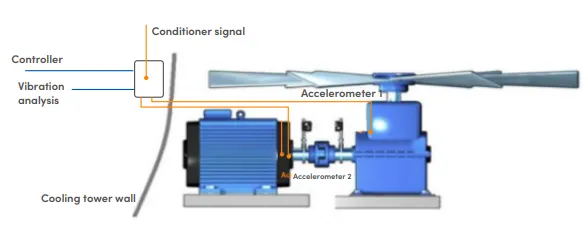

Measuring key vibration parameters and analyzing vibration data from a cooling tower are the most important actions to take. To collect vibration data on gear-driven fans, it is necessary to monitor both the motor and the gearbox.

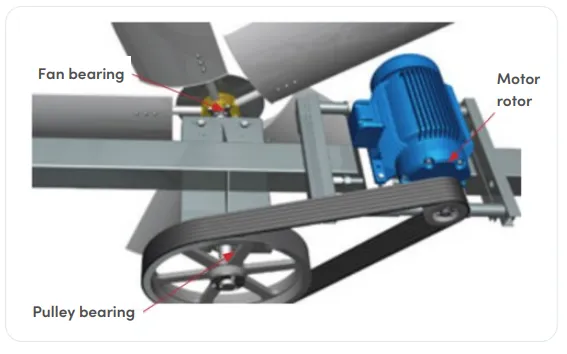

For belt driven fans, vibration of the fan inner bearing, motor inner bearing, and intermediate bearings on the fan shaft should be monitored.

Monitoring points on fan with gearbox

Monitoring points on fan with pulley and belt

Mounting points for vibration sensors

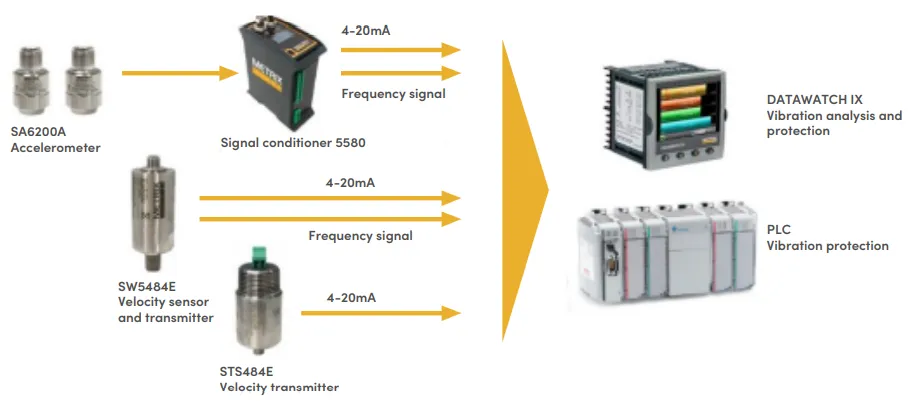

Solution architecture for cooling tower protection