Batch control (ISA-88) recipe formulation

ANSI/ISA-88 norm commonly known as S88 standardizes batch production needed in the food and pharmaceutical industries for efficiency and flexibility in the making of recipe based products.

S88 is a design philosophy used for describing equipment and sequences which define the physical model, procedures and recipes.

It will help you generate a multiple product batch management on shared equipment, designed to automate, make more flexible and provide a complete production history record in compliance with the ISA-S88 norm.

This attempts to solve four fundamental problems of batch processes:

Process arrangements

ISA S88 has been the main basis to develop software tools in charge of automation of production processes based on recipes developed on a design philosophy used to describe equipment and following procedures no matter the kind of process.

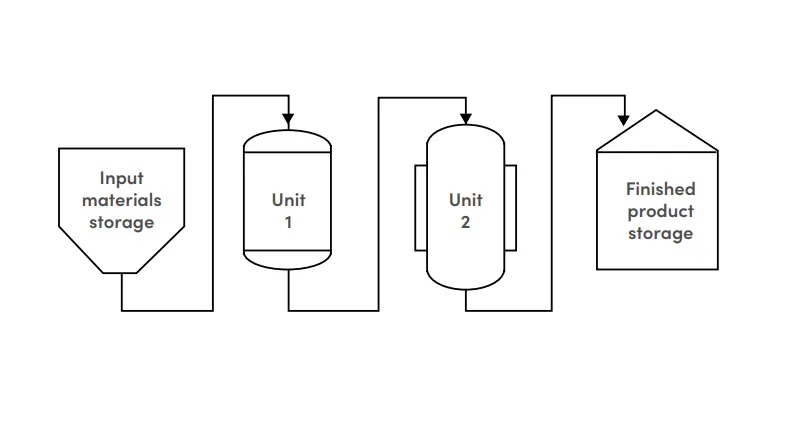

Singular

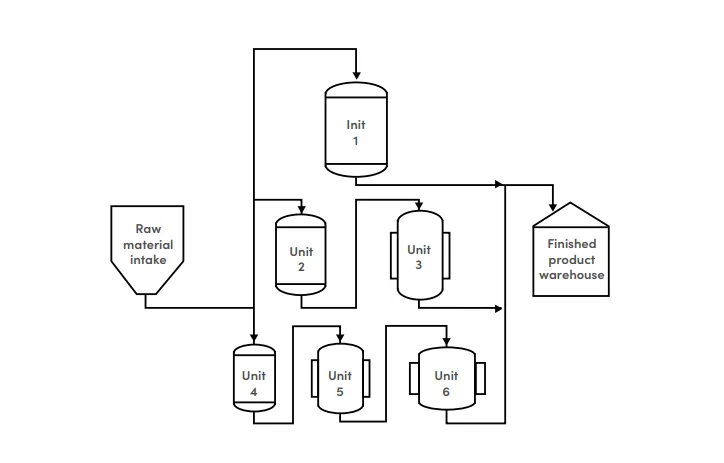

Multiple

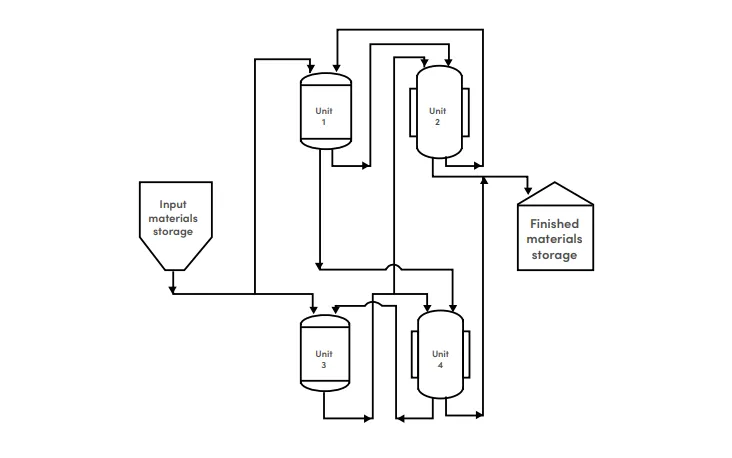

Structure

Batch Control

ECN Automation develops S88 based projects through FactoryTalk® Batch, tool designed by Rockwell Software for batch system control modeled under the standard S88.

Factory Talk Operation Suite Platform

Control capacity all over the plant

Get rid of the need of having several heterogeneous and different control systems integrating the batch in the controller with a discrete control, power, safety and information in a single infrastructure for the whole plant.

Flexible and scalable architecture

FactoryTalk® batch based in ISA-88 allows you to integrate total batch control having the recipes of different products as well as process equipment configuration required for production, without having to reconfigure or reprogram with every single change of product.

Engineering and development

ECN Automation solution partner certified by Rockwell has the abilities, knowledge and experience to develop batch production projects based on ISA-88 on the FactoryTalk® batch platform by Rockwell.

FactoryTalk® Batch system key advantages in projects developed by ECN Automation

Process screen