Manufacturing and medical devices

Population growth, the increase in health expenditure, the incidence of chronic diseases, the development of the manufacturing industry and the acquisition of new technologies are factors that contribute to an increasing dynamism in the production of medical devices. For efficiency and energy savings in the manufacture and production of these, they are important.

Manufacturing Execution System MES

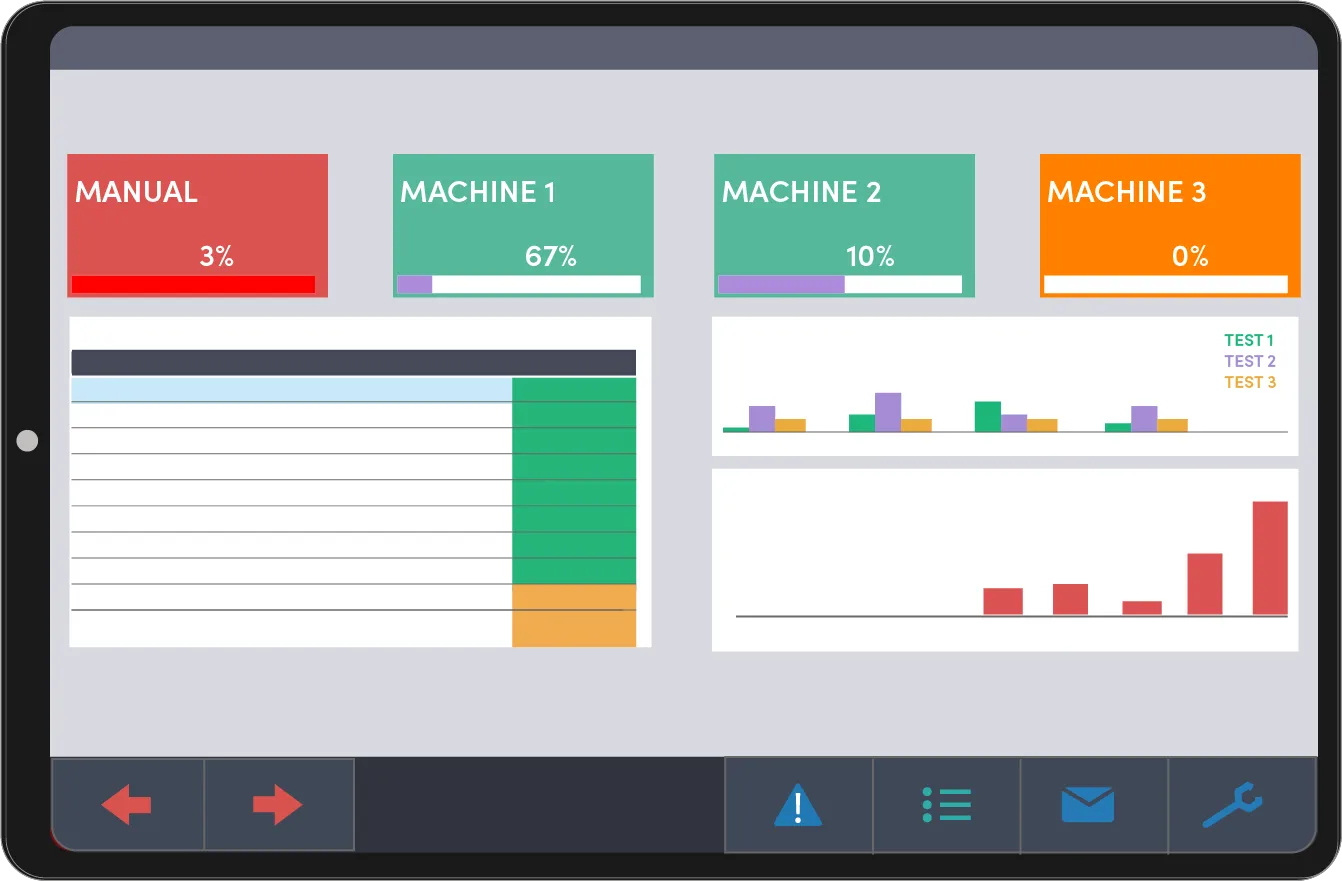

MES system will allow you the control and global management of the information of all your production plants and the perfect integration of the data with your ERP. It integrates the different modules of the solution in an environment that is easy to use and quick to implement, where valuable information can be displayed to make timely decisions.

Modules

Production control

Quality and traceability

SCADA

Dashboards

O.F. Planning

Rolling Mill Management

Production

Quality

Maintenance

Traceability

MES Solutions

OEE Production

Global control and management of your factories, fully integrated with your ERP, the solution uses automatic data capture from any machine or sensor to obtain objective, reliable and real-time data.

Energy efficiency

In a simple system for registering parameters or variables that vary over time. The system communicates with any industrial device that has a communications output or a voltage or current output.

Predictive Maintenance

It assesses the state of the machinery and recommends intervening or not depending on its state, which produces great savings.

Traceability

It allows the management of manufacturing batches, raw materials, semi-finished products and the final product.

Business intelligence

BI centralizes information for a simple structure, creating dynamic screens and reports based on customer needs.

Quality

Quality management system that will allow you to have a reliable and fast control of all the information in your department.

Characteristics

Benefits

Compatible on any type of device

Monitors

Tablet

Smartphone

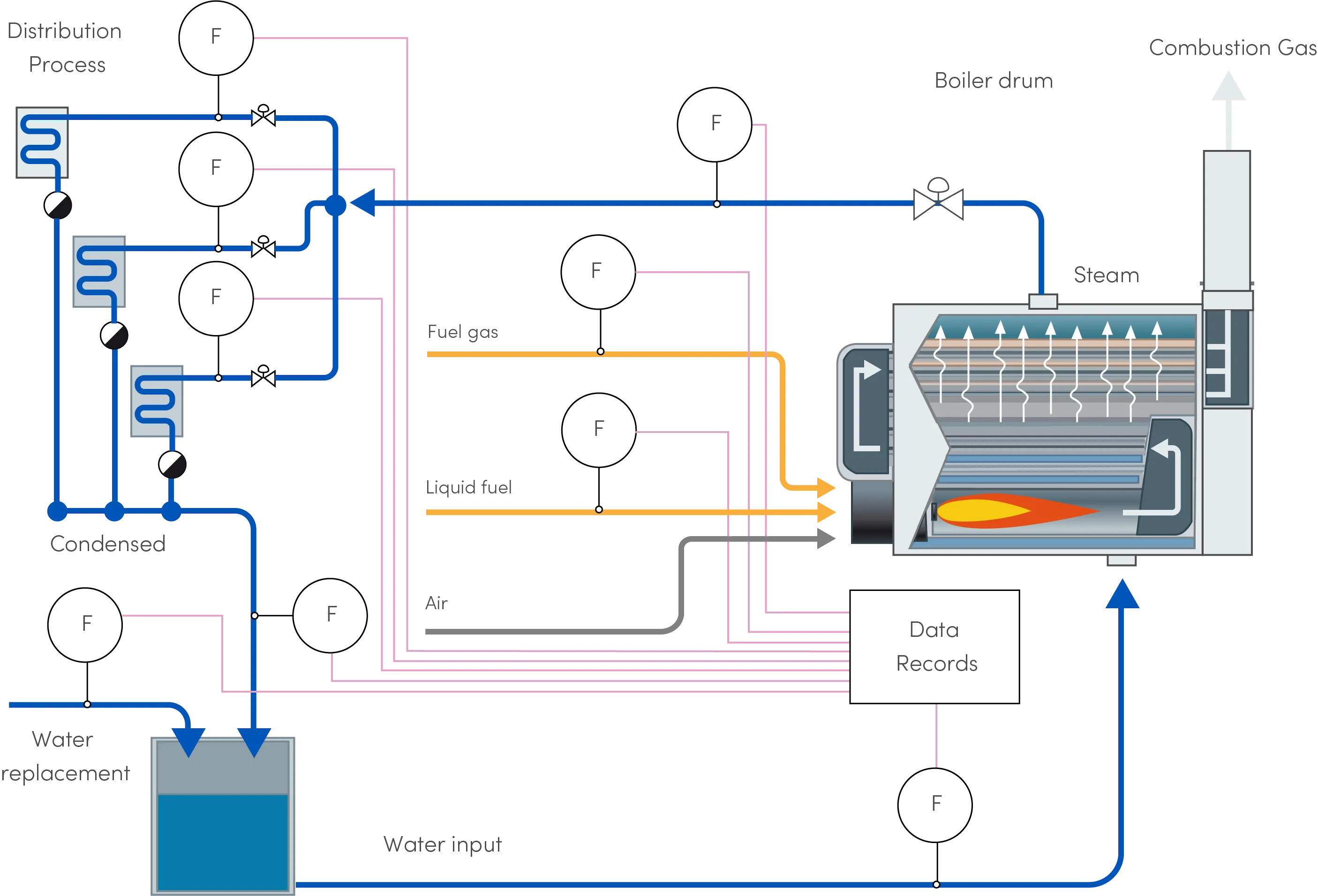

Boiler Efficiency

Whether determining the current performance of your existing boiler equipment, optimizing plant operation, or evaluating flue gas consumption, you can rely on our experience and industry knowledge. Improvement of boiler control and plant safety through advanced measurement and monitoring solutions. Efficiency through compliance and cost per consumption unit.

System advantages:

Steam

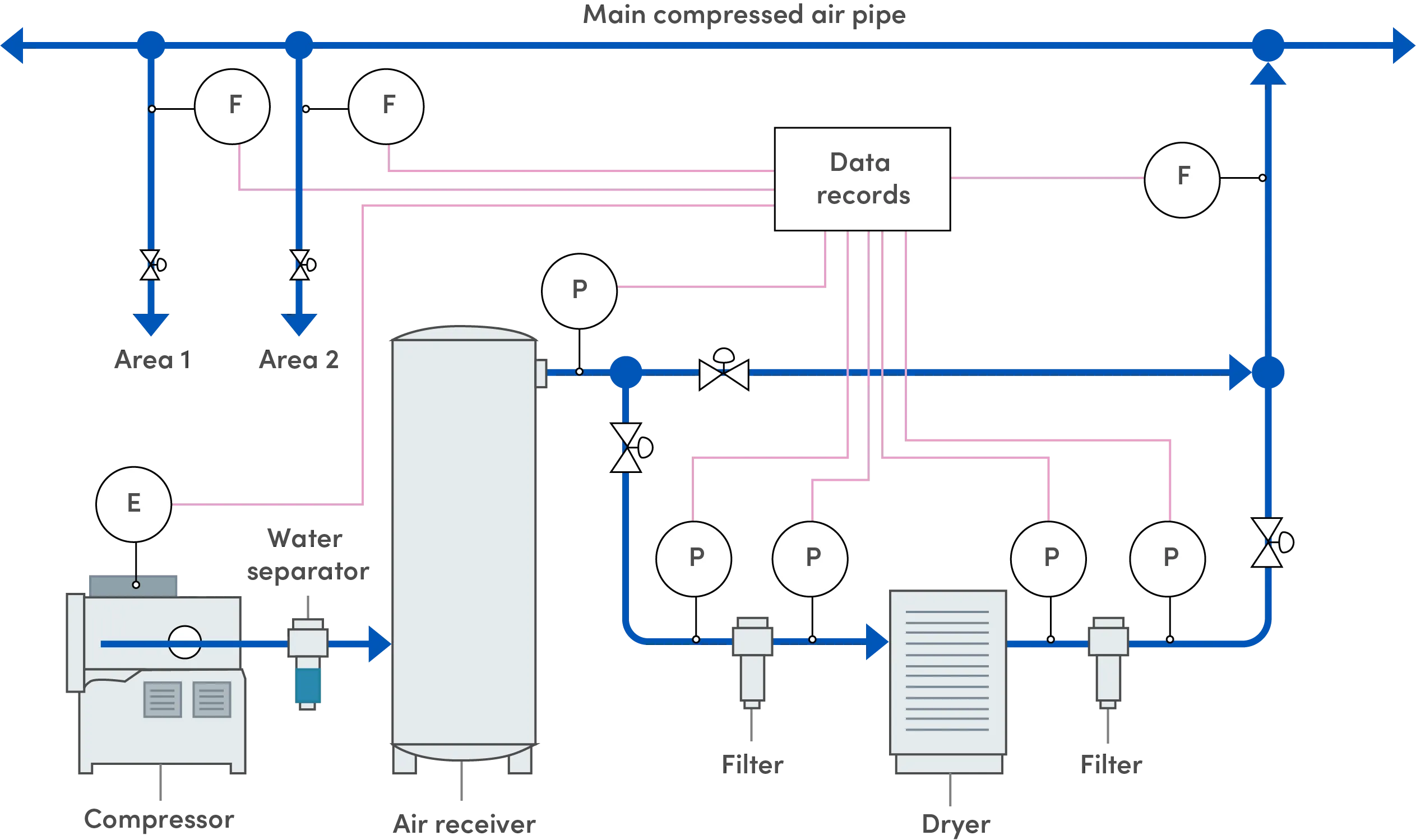

Compressor Efficiency

The use of meaningful KPI indicators keep operators informed, as well as management. This energy management can be done constructively. Since up to 85% of the total costs of a compressed air system are mainly energy costs.

To determine the efficiency, we have:

Using flowmeters at different points in the system, implemented this solution we can:

Energy solutions - compressed air applications