Laboratories and Pharmaceuticals

The production standards of the pharmaceutical industry are strictly adhered to regulations that control the active contents, the formulations, the quantities produced as well as the sterilization of any part that touches the product and finally the control of the environment where it is produced.

The design and specification of instrumentation, automation and information systems ensures compliance with and traceability of these regulations, as well as efficiency in the operation of processes.

Quality water

The quality of the water plays an important role in the production of pharmaceutical products, such as the water used for injectable solutions, which must monitor analytical values in all of them in order to guarantee the quality of the water. Another important point is to prevent the microbial load, therefore the water must be kept moving.

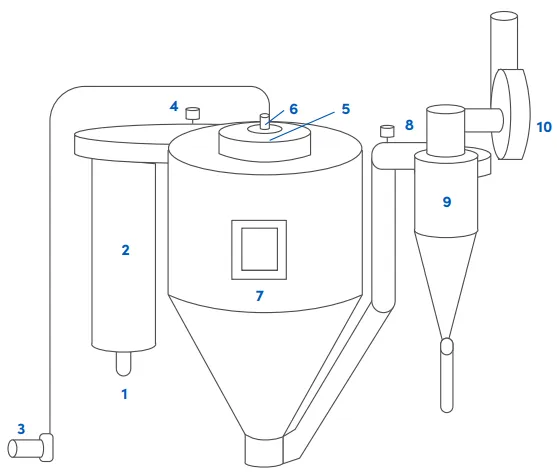

Water production (purified water - PW)

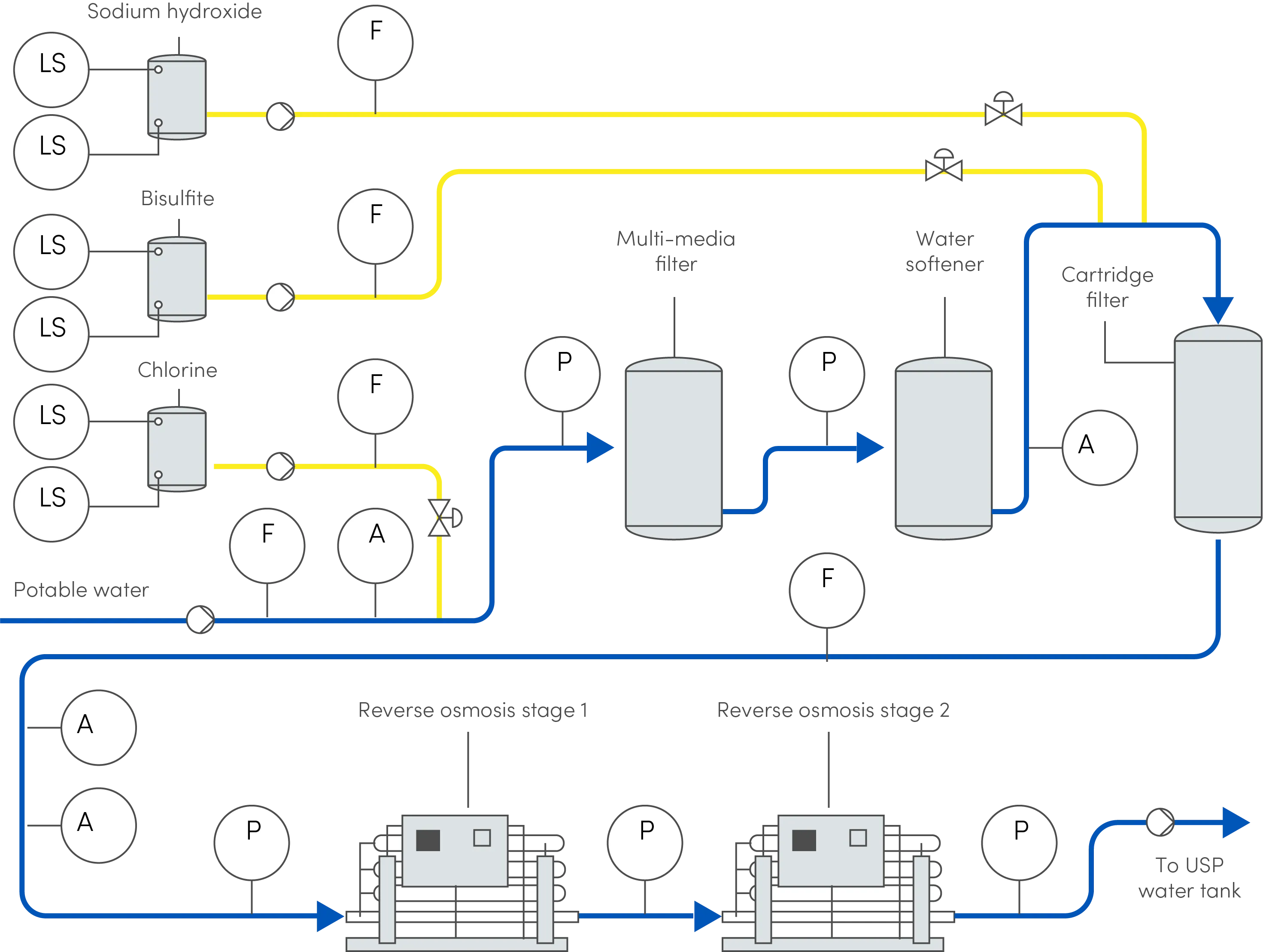

Batch process formulation

Formulation is the most demanding step in the manufacture of pharmaceutical products and is the key to determining the quality of the final product. The precise addition and mixing of raw materials requires precise control, as well as the reliability of measuring instruments to guarantee a quality product that complies with established understandings and regulations.

Advantages of a Batch control

Batch Mixer Diagram

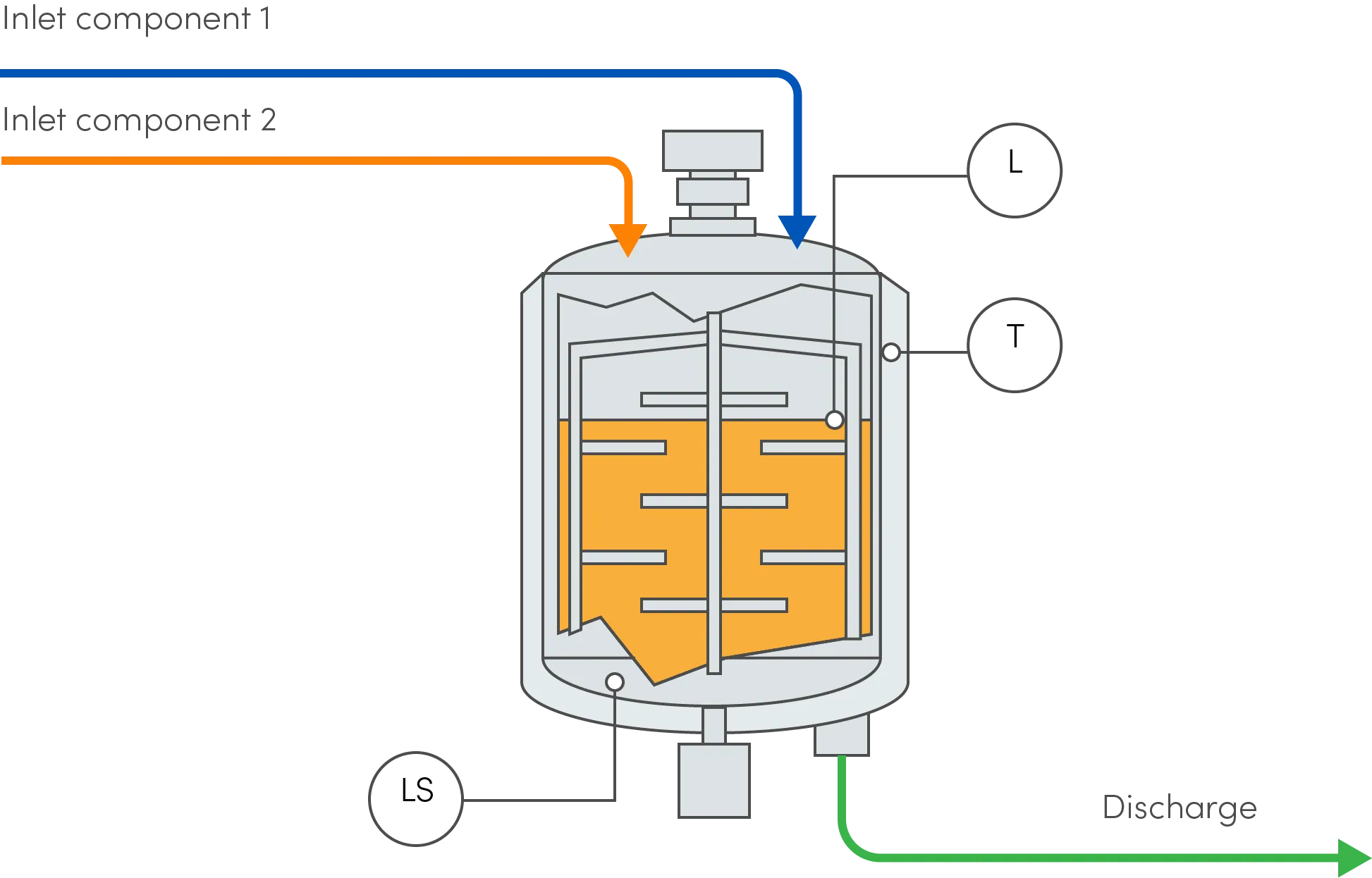

Bio-decontamination of clean rooms.

Vaporized hydrogen peroxide (VHP) is generated by actively vaporizing an aqueous solution of hydrogen peroxide and injecting it into a room. Achieving a high rate of bio-decontamination of microorganisms requires setting a high concentration and exposure time. Due to the type of process and risks to personnel, it is necessary to monitor these rooms.

Benefits of constant monitoring in clean rooms

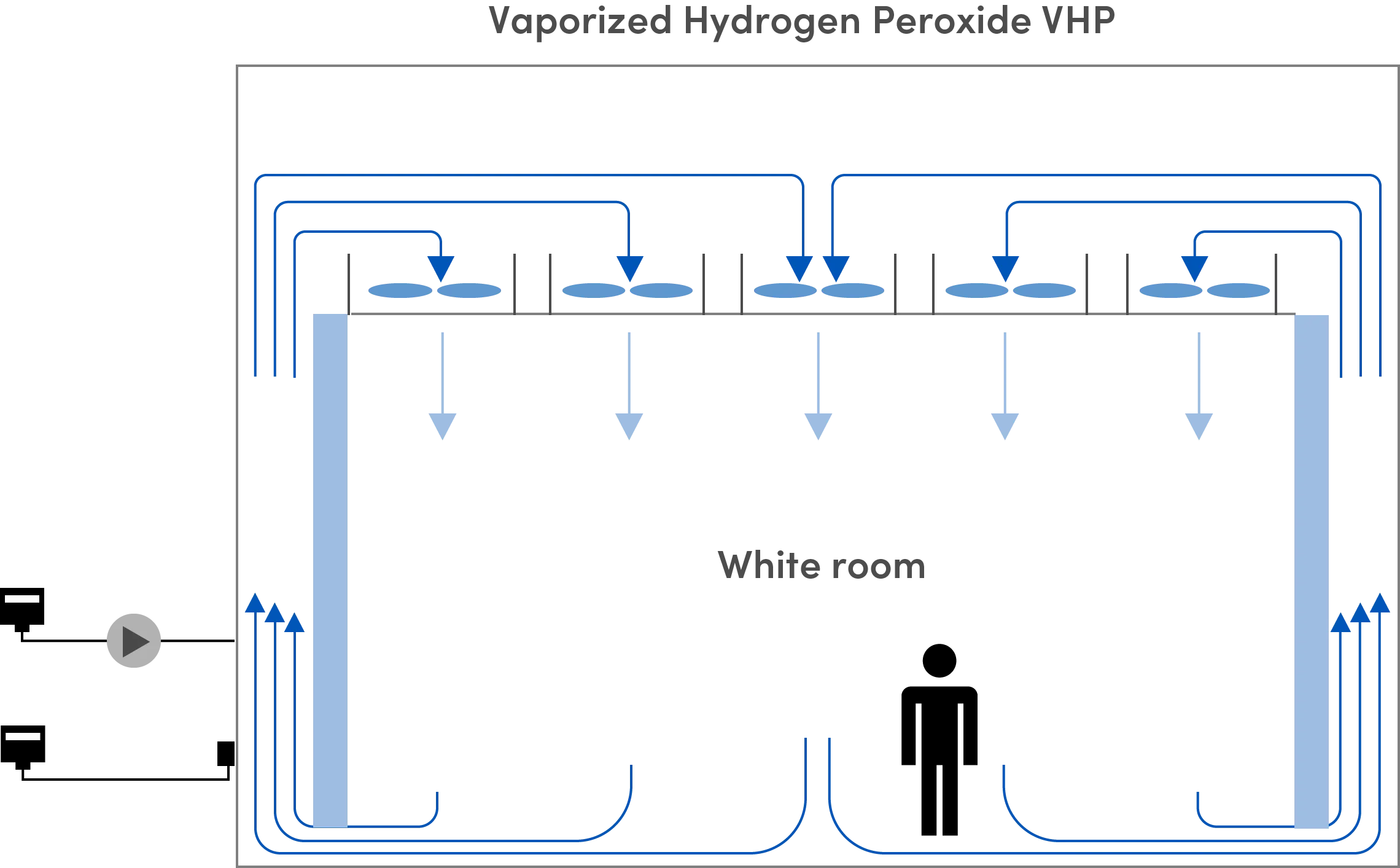

Granulation process

Granulation is an operation whose purpose is the agglomeration of finely divided or pulverized substances by pressure or the addition of a binder dispersed in a liquid. One of the most used methods is wet granulation with fluid-bed systems or spray granulation are systems used for drying and wet granulation.

The process of adding a liquid solution to powders involves kneading a mixture of primary dry powder particles using a granulating fluid.

Spray dryer

Main components:

Parts:

Optional Components