Home care

The home care industry is concerned with the production of consumer items necessary for cleaning, hygiene, disinfection and a pleasant environment in the home.

The production of home care items, being a consumer industry, requires mass production systems that meet the requirements and formulations of each product, to meet quality and standardization, as well as the efficiency of the processes, it is necessary to implement instrumentation, automation and information systems tailored to each process.

Manufacture of liquid detergents

Liquid detergents for their part are increasingly better accepted among consumers. These detergents are often less effective than their powdered counterparts. This is due to the difficulty in incorporating ingredients such as zeolites, phosphates and certain bleaching agents into them. Manufacturers try to compensate for these technical problems by increasing the concentration of surfactants in the formula.

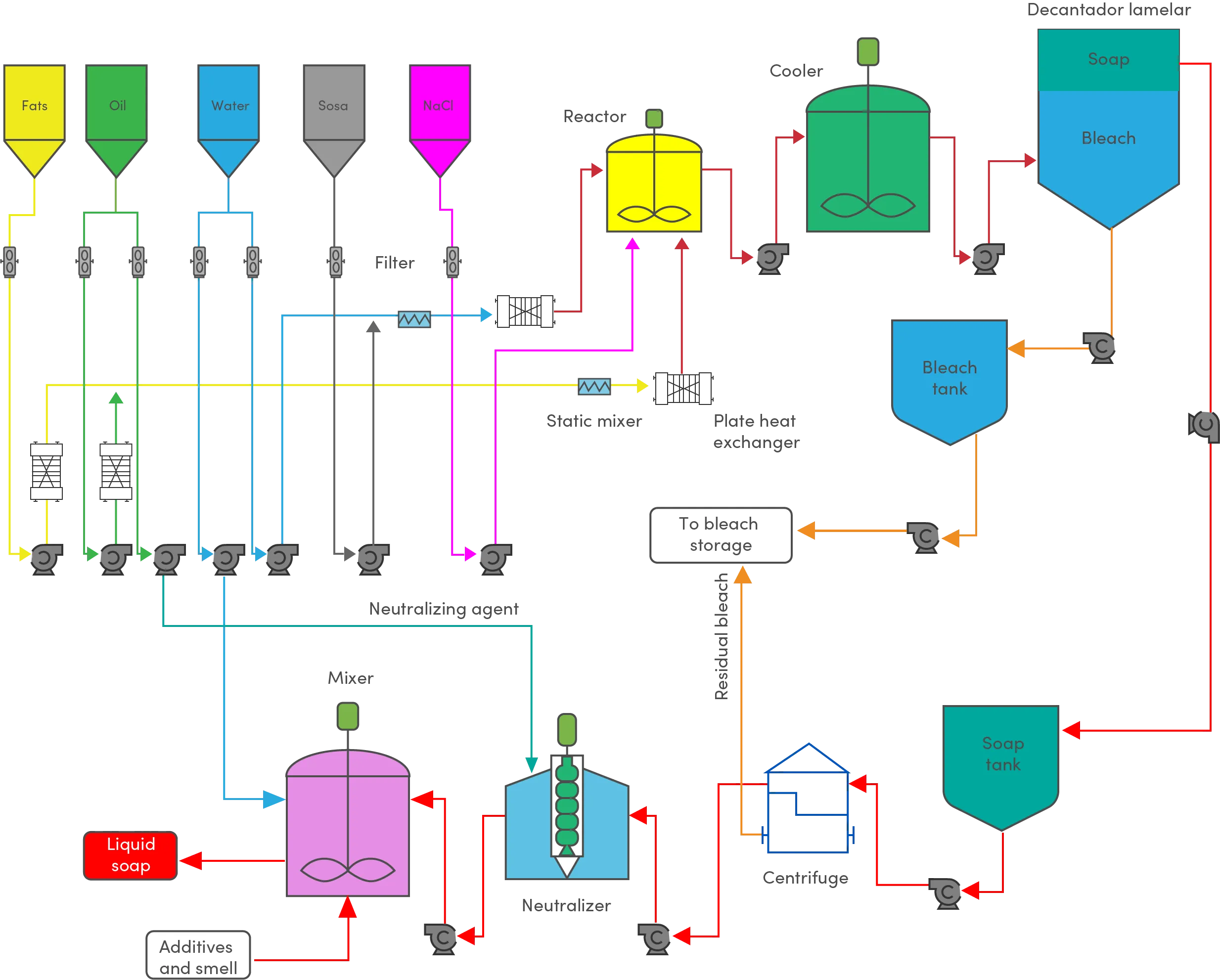

Flow diagram for the production of liquid soap from the saponification of animal fats and palm oil

Batch process formulation

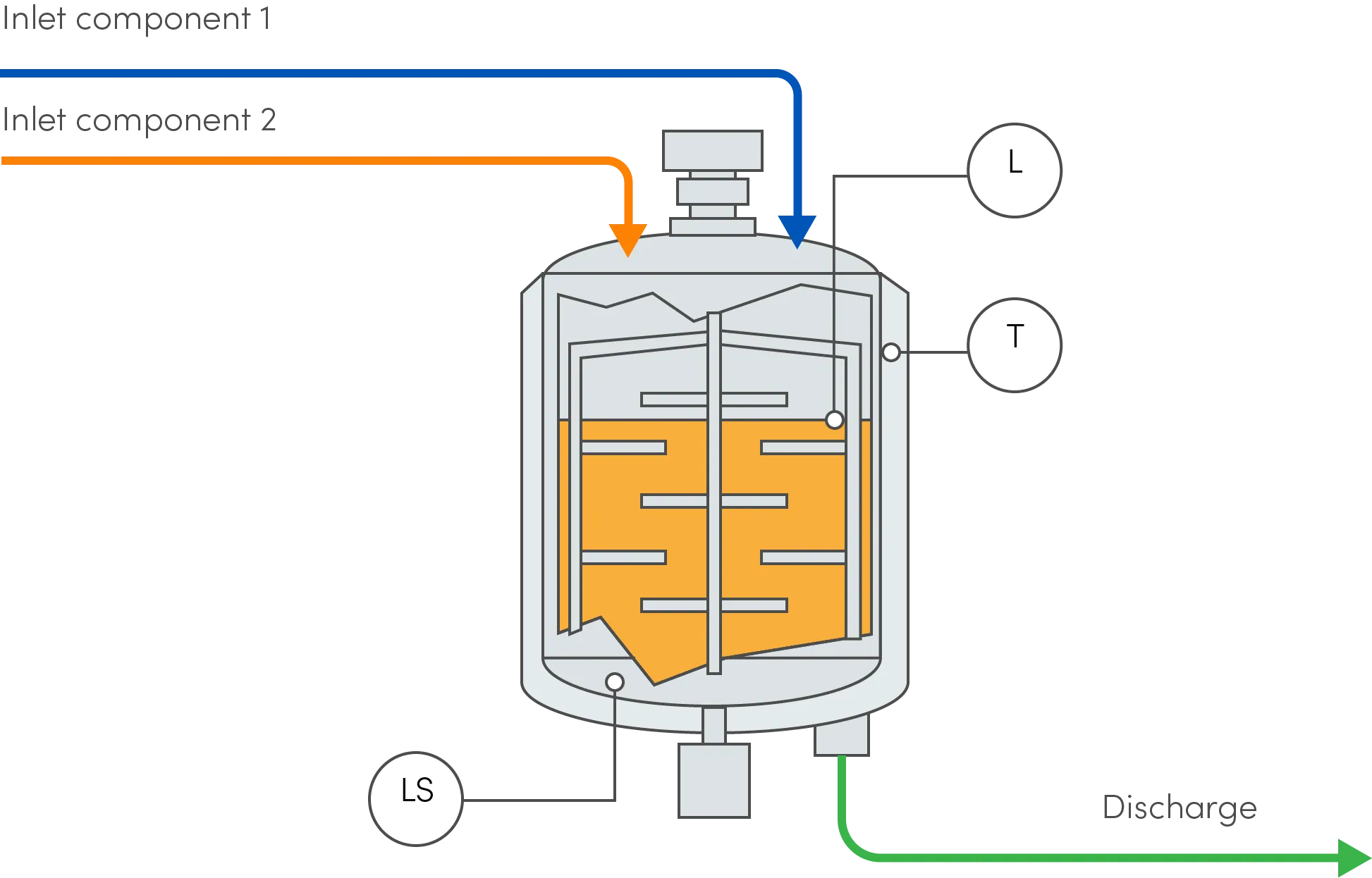

Formulation is the most demanding step in the manufacture of pharmaceutical products and is the key to determining the quality of the final product. The precise addition and mixing of raw materials requires precise control, as well as the reliability of measuring instruments to guarantee a quality product that complies with established understandings and regulations.

Advantages of a Bach control:

Batch mixer

Batch mixer diagram

Drying to produce soap powder

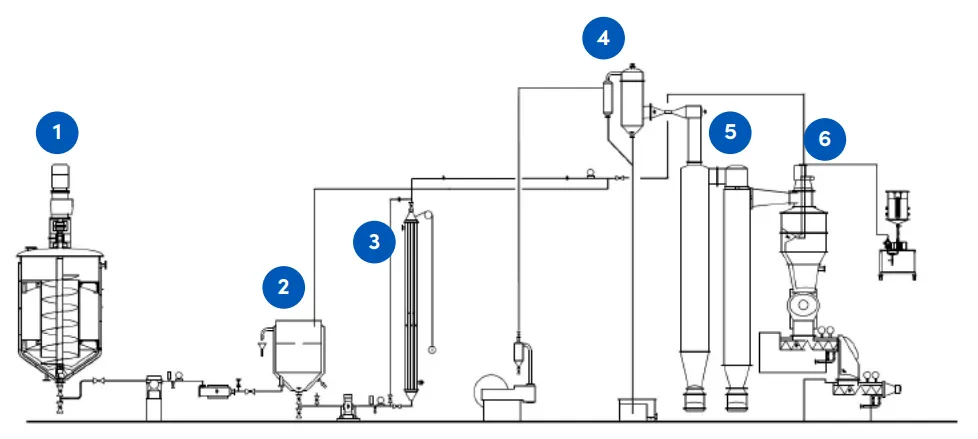

Liquid soap is splashed into the atomizer. The controlled combination of temperature and vacuum allows the water to evaporate, obtaining the desired degree of moisture in the soap. The vapor separated from the soap is vacuumed. The soap is scraped from the internal walls of the atomizer by means of spatulas and is precipitated until it falls into the compressor/extruder.

Process diagram of: drying soap powder