Moisture and flow measurement solutions in powders and granulaes

In different processes of the food and beverage industry, is important to measure the bulk material flow and moisture in line, such as flours, sugar, powder milk, powders and granulates in general.

This quantification is needed to know the production, material reception or dispatch, mass balance inventory or process control.

Powder or granulated products used in the food and beverage industry

Grains: corn, oatmeal, malt, barley, rice.

Powders: flours, powder milk, sugar, salt, yeast, pectin.

Transportation of these products is done via pneumatic systems, mechanical and sliding conveyors.

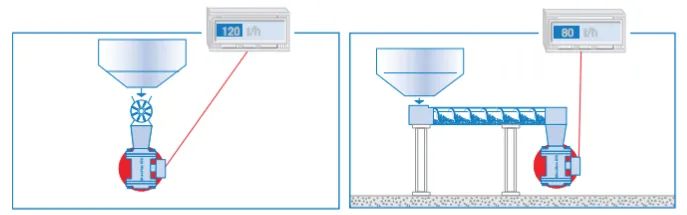

Free fall measurement after conveyors:

13.18.07.webp)

MaxxFlow HTC

Electromagnetic

SolidFlow 2.0

Microwave

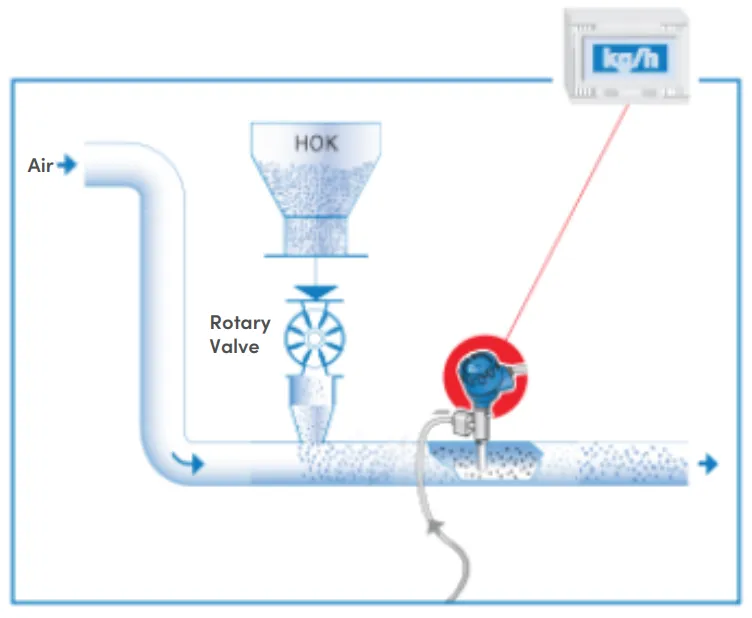

Pneumatic transport measurement:

13.26.42.webp)

MaxFlow HTC

Mass flow meter for dry solids in bulk

13.26.49.webp)

SolidFlow 2.0

Solid volume measurement up to 20 t/h

13.26.57.webp)

DensFlow HP

Flow meter for dense phase transport

13.27.04.webp)

SlideControl 2.0

Flow monitoring in air chutes

13.27.13.webp)

PicoFlow

Flow meter for low solid/air relation

13.27.22.webp)

DensFlow

Flow meter for dense phase transport

Speed monitoring

Speed monitoring is an important process variable for powders and bulk materials transportation in order to regulate the transportation velocity and to predict stuck materials in a pipe line.

13.50.19.webp)

SpeedFlow 2.0 tube

Speed meter, material transport

13.50.30.webp)

SpeedFlow 2.0

Speed meter for solids

Moisture measurement solutions in powders and granules

Moisture

Moisture in line measurement of powders and granulates is needed to know the trace of humidity in the product for quality control, product quantification, and process control.

13.46.52.webp)

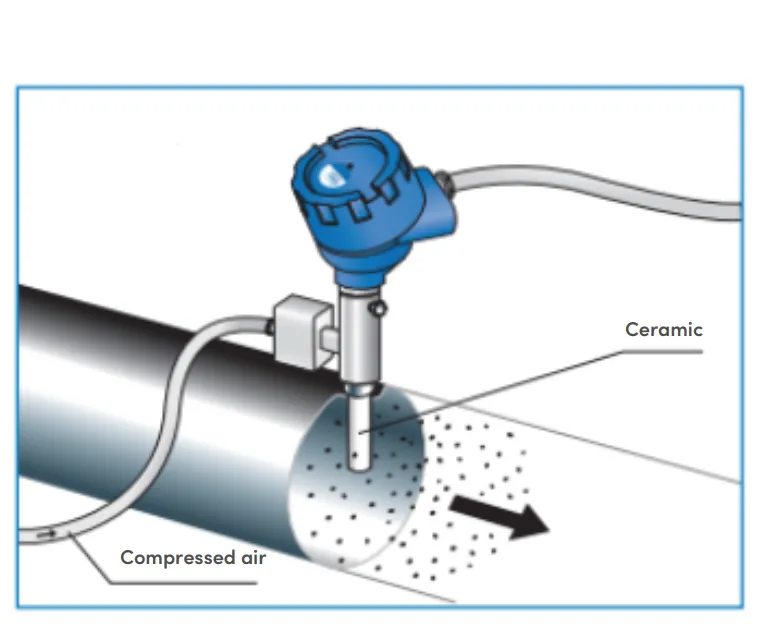

M-Sens 3

Moisture meter with temperature indicator and material flow control

13.47.09.webp)

M-Sens WR

In line trace moisture meter

M-Sens 2

In line trace moisture meter