Digital transformation in the food & beverage industry

Consumers preference for more specific products has made of technology an essential factor for the sector’s evolution. Costumers tendency for healthy, organic, fresh, local products and their concerned of environmentally friendly companies at the same time, have impacted the development of a different food & beverage industry.

This F&B industry evolution, leverage the Industry 4.0 technology for advanced production to complied with higher standards and challenges of the costumer preferences.

What do you need?

At ECN Automation we have a solution

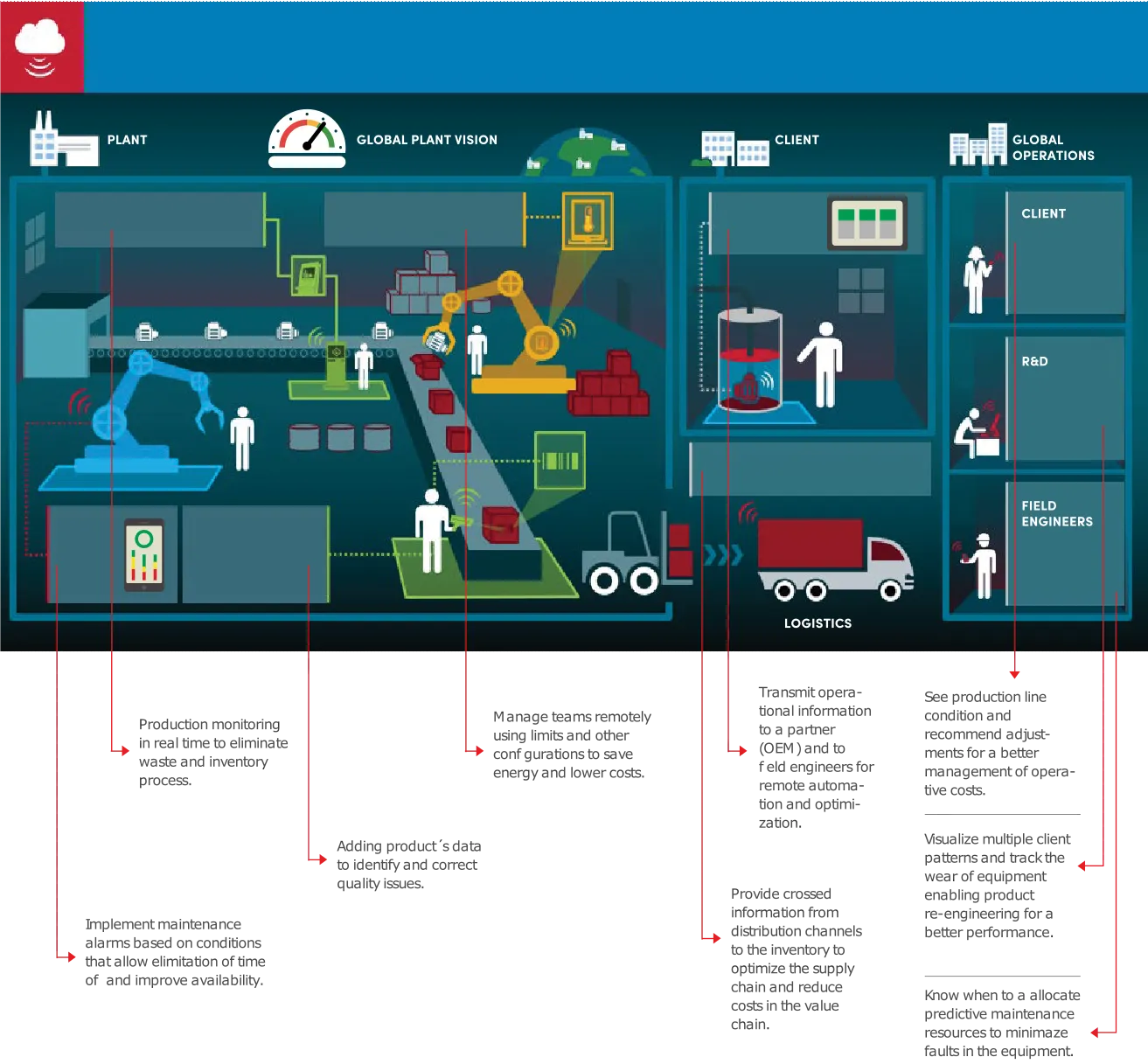

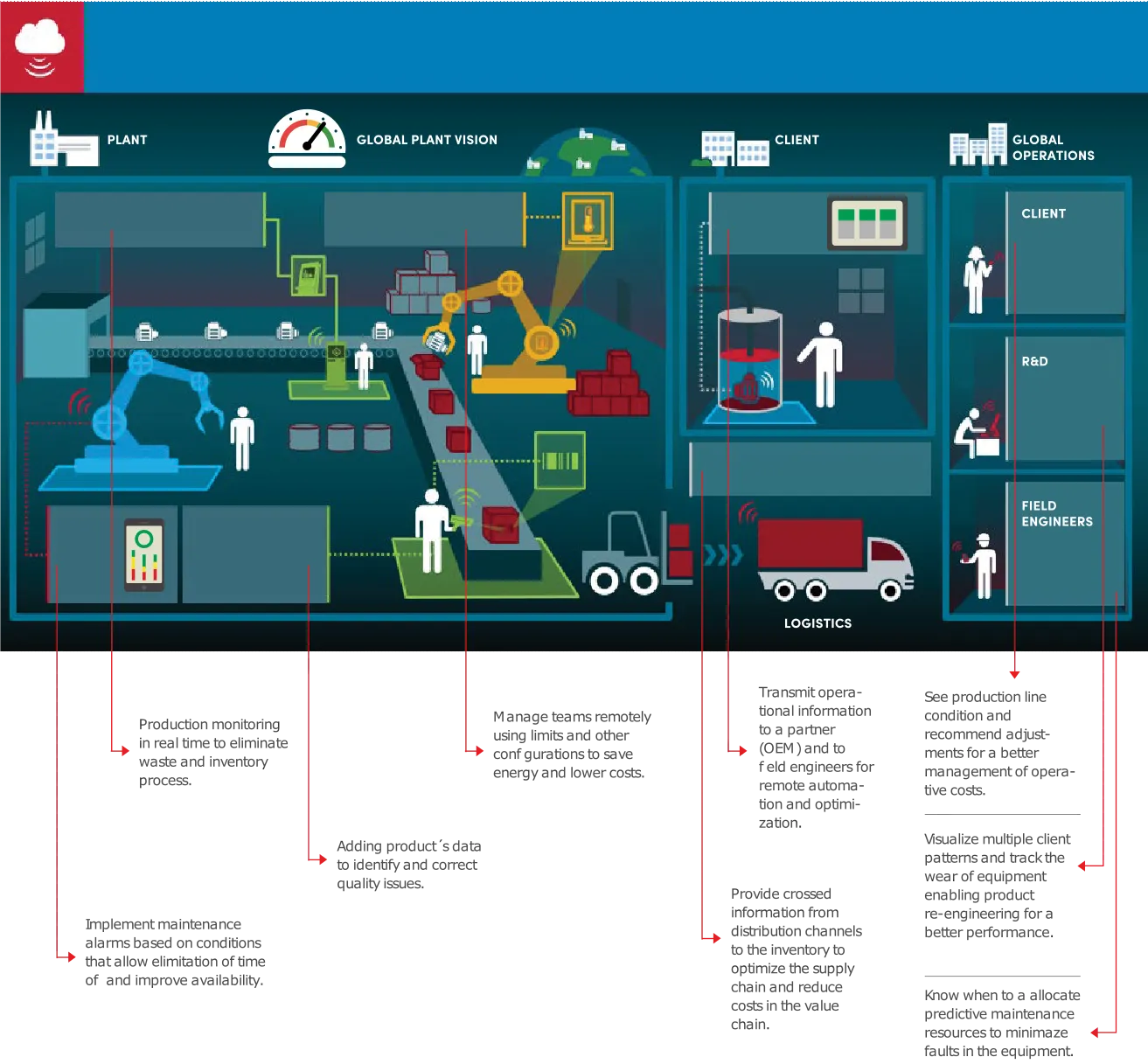

Connected Industry

Factory communication infrastructure is the gateway to digital transformation. Connected smart devices open new windows to process visibility. Data and analysis allow better and faster decision making. Transparent connectivity encourages new collaboration.

Connected industry makes all of this possible. It unites business and plant level networks and safely connects people, processes and technology.

Industrial ethernet infrastructure

One of the most widely used communication standards nowadays is Ethernet. With industry 4.0 the aim is to have as much connected equipment as possible thus a robust, resilient and safe network infrastructure is needed.

ECN Automation has developed best practices and knowledge for the engineering design and network projects execution with many application references and success cases.

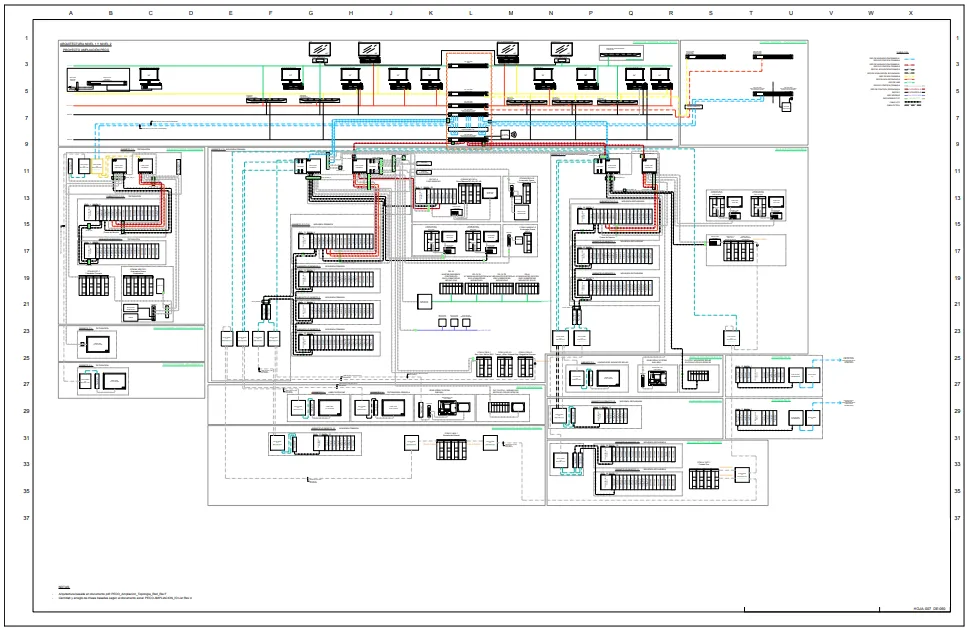

Network architecture

At ECN Automation the creation of network architecture for industrial environments (OT) is made following design guidelines and implementation for the development of converged plantwide Ethernet in plant architecture (CPwE). This guideline allows us to correctly implement different network topologies with the newest tech, implementation risk is reduced considerably since the different architectures shown in the document have been validated and approved by Rockwell Automation collaborating with Cisco. Following these guidelines we ensure that our industrial network architecture be scalable, solid and safe.

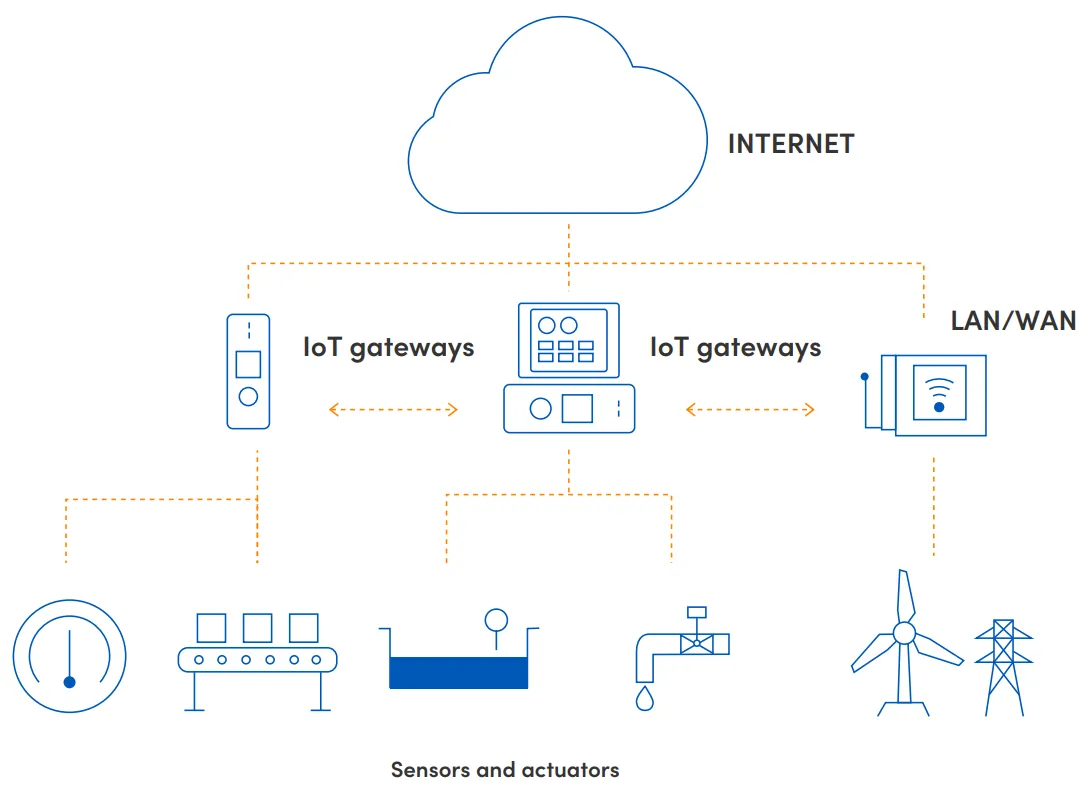

IoT Connectivity

IoT connectivity technology provides the network architecture and communication capabilities that IoT devices require to gather, transport and exchange data through the internet and be monitored and controlled remotely.

IoT connectivity consider different network media technologies necessary and concentrated data from different sources:

Arquitecture

Connected industry scheme

Cyber security (Firewall, DMZ)

Set of procedures and tools implemented to protect the network and information infrastructure generated and processed through computers, servers, mobile devices, networks and electronic systems.

It is important to consider 4 main points which help guarantee the safety of the information:

1.

Confidentiality:

Resources, data and information can only be accessed by authorized users.

2.

Integrity:

Only authorized users must be able to modify data when required.

3.

Availability:

Data must be available for users when needed.

4.

Authentication:

Verify that you are really communicating with who you intend to.

What you want to protect:

Software Security:

Threats do not always come through physical means, to guarantee software security, it is important to apply security measures related to these environments, for example, using an antivirus software, set rules to allow or deny access to certain internet websites. One of the main risks found is not having updated equipment.

Hardware Security:

Provide protection to the entire network infrastructure like routers, switches, servers and/or controllers. It is important to use Firewalls in charge of avoiding threats and meddling into the network.

Network Security:

Apply good practices which lead us to the protection of data on the web, thus offering these 4 specific information security points: confidentiality, integrity, availability and authentication.

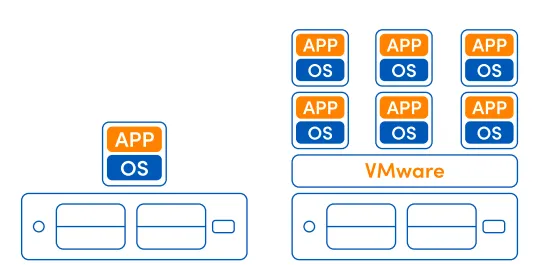

Virtualization

Reliable solution in which it will be possible to allocate more than one application in the same server, with centralized easy administration of its apps, storage and networks.

Benefits:

Mobility

Current operations dynamics requires information access anywhere at any time. The capacity of communication networks and cyber security give us a reliable platform to do so.

Applying mobility we can access information in data servers, linked devices, CCTV and other in plant information sources anywhere outside the control room, this lets us visualize the operation, access reports, alarms or process indicators through mobile devices.

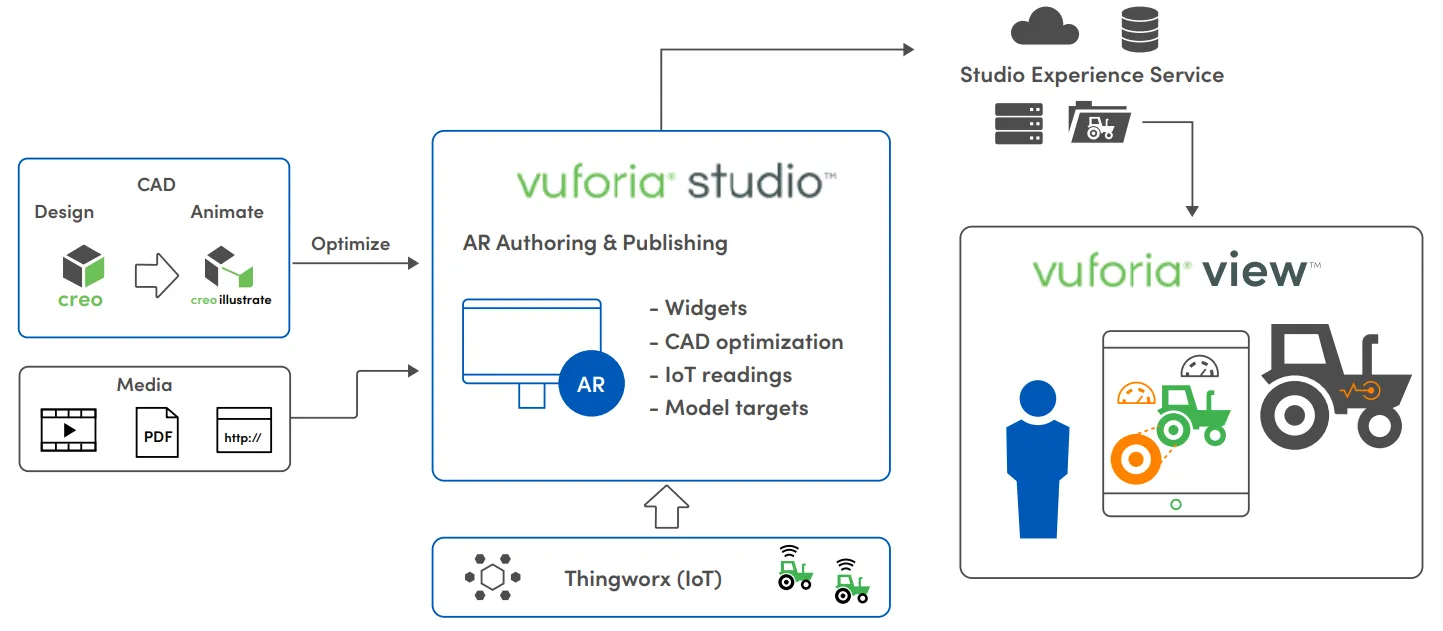

Augmented Reality

Our solution combines information for mobile users through an interface that overlays data in real time and virtual objects in machines, control panels or processes; allowing users immediate access to relevant machine and process information.

This technology can be applied to visualize process data in real time, visualize technical sheets / plans, videos as well as procedures to carry out a specific task. Thanks to this technology it is possible to digitize and centralize all the documentation of your process to be able to consult it at any time.

Solution architecture

This solution allows the information from the existing control systems in the plant to be connected to a central station where the augmented reality application is running, a WIFI connection enables the contents so that they can be displayed on mobile devices such as tablets and cell phones.

Create & scale industrial AR

Benefits:

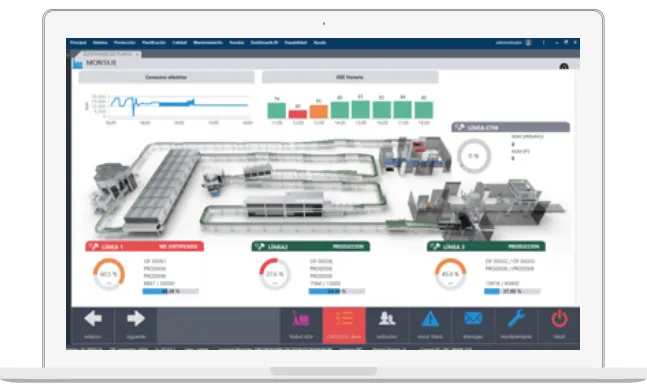

Manufacturing Execution System, MES

State of the art MES platform that will allow you the control and global information management over all your production plants and perfect data integration with ERP.

The MES system is based on the powerful Mapex Business Platform (MapexBP) that integrates the different solution modules in an easy to use and quick to implement environment where valuable information can be shown to make accurate decisions.

Data gathering for production control

Quality control and traceability

Have the quality control and traceability that provides you with all the necessary tools for the improvement of the quality control department and the plant.

Where can I apply the MES system in my plant?

MES Systems (Manufacturing Execution System)

BI Tools