Soft drinks and juice

The soft drinks industry keeps transforming and adapting to current times and the lifestyle of consumers.

In the last years, evolution of the soft drinks market in the world has been reoriented to a healthier focus less sugar content, natural ingredients this is a great opportunity for companies in this sector to grow

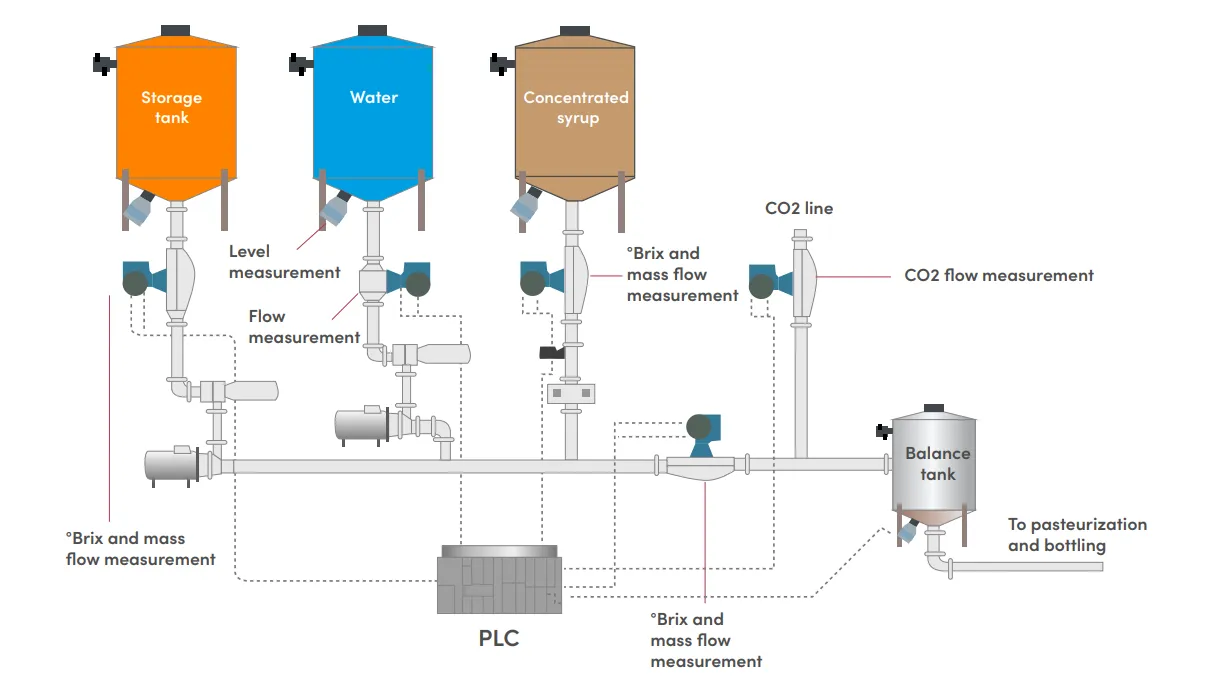

Preparation

Water is the main ingredient, it can come from a municipal supply greed, a well or a spring. Drinking water goes through several treatments to produce the soft drink. Sugar and sweeteners are added to the water as well as vitamins, caffeine, aroma, etc. Different combinations provide a wide variety of products.

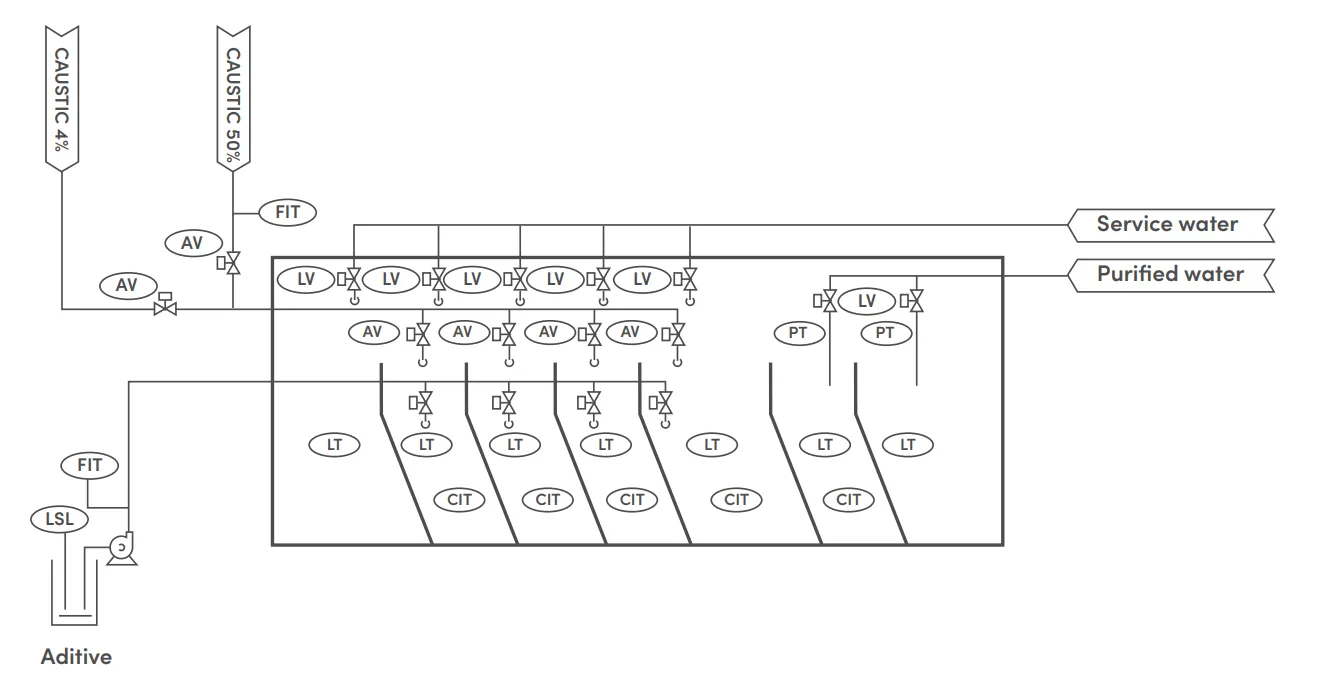

Bottle cleaning

A highly important area in the soft drinks industry is the cleanliness of reusable bottles and to guarantee the absence of dirt.

On regards of energy consumption and cleaning agents, the washing system is one of the main consumers, thus having an accurate control is a must in order to guarantee the system's efficiency.

Bottle washer integral control system

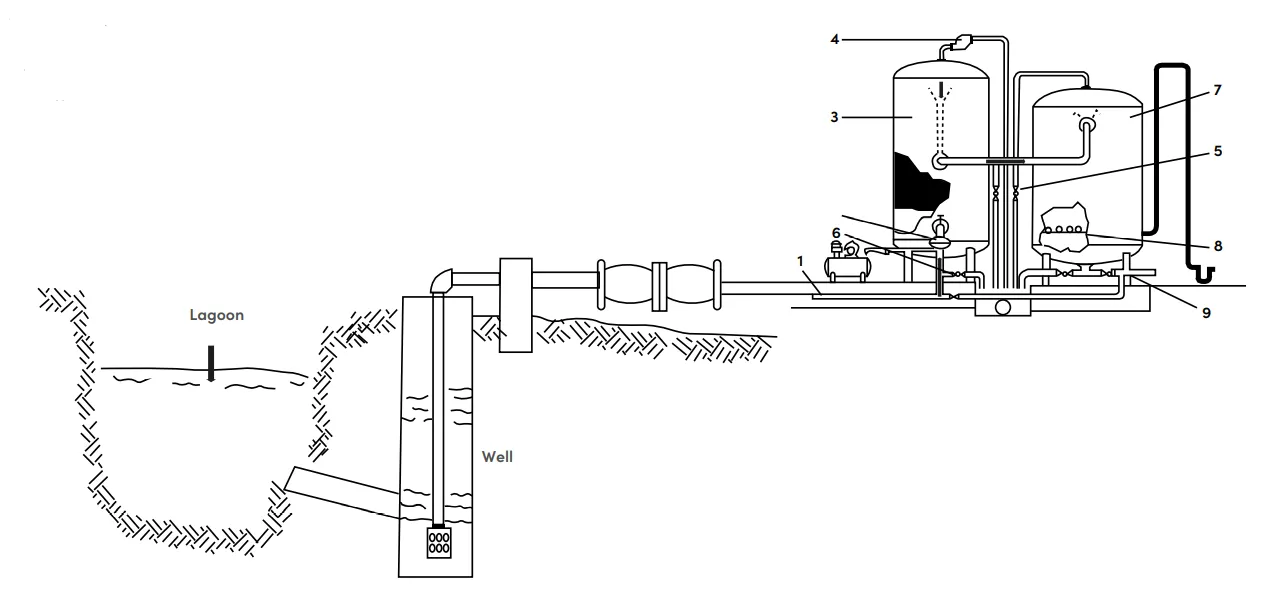

Raw water treatment

Water is essential in the production of juice and soft drinks, which is why it’s important to have a raw water source that can be surface water or subsurface. It must go through treatment to remove all kinds of impurities and organic load before starting the process.

Some water treatment stages are:

Reagent dosage - initial sanitation

At this stage aluminum salts are added to pretreated water so that smaller particles gather and get rid of through later decantation.

Filtration

In order to eliminate the rest of the particles in total, water is then filtered through sand filters. As a complement for this filtration and with the objective of improving its organoleptic conditions, ozone can be dosed to then add absorption through active carbon. This last step eliminates organic elements and metallic oxides in water.

Final disinfection

Water is stored awaiting distribution by the grid; it goes through another chlorination process if it is under minimal requirements by law.

Filtration system diagram